MAHLE® pistons are OE quality and have many premium OE features. Pistons have to put up with extreme pressures, as their working conditions have become significantly tougher in recent years. Naturally, the demands on pistons have also risen progressively: they must be lighter, must have lower oil consumption and must be absolutely safe and reliable.

MAHLE pistons feature:

- COMPENSATED RING GROOVES assure proper ring loading and oil control.

- EXPANSION CONTROLLED DESIGNS for small fitting clearances. With the tighter fitting clearances comes reduced engine noise, reduced wear, reduced emissions and improved oil control in the long term.

- PIN OFFSET for reduced engine noise.

- LIGHTWEIGHT DESIGN for reduced reciprocating mass without sacrificing reliability. This reduces bearing loads, offers smoother engine running and improves engine response. Consider, for example, the MAHLE design for the Chevrolet 4.3L 200 HP truck engine. At 520 grams, the piston is 15% lighter than other pistons offered by Chevrolet for this engine.

MAHLE pistons are reliable. In many instances, MAHLE is asked to supply the pistons for an OE manufacturer's high output, premium engines. The Chrysler 2.5L Turbo, Chevrolet 5.7L LT5 (ZRI Corvette), Chevrolet 5.7L LT1 and Chevrolet 4.3L 200HP truck engines all have our pistons.

MAHLE's eutectic (12% silicon) aluminum alloy is performance proven in literally millions of engines around the world including high output diesel engines and Formula One racing.

Piston Fitting Clearances

The MAHLE® repair pistons are ready for installation with mounted piston rings.

Piston diameter, installation clearance, and if applicable – direction of installation are marked on the piston crown. The stated piston diameter added to the corresponding clearance gives the cylinder diameter.

In the case of pistons that have a graphitized skirt, another 0.015-0.020 mm should be deducted from the measured piston diameter to allow for the thickness of the layer; this gives the nominal diameter for the piston which is stamped on it.

| Example: | |

| Measured diameter on layer of graphite | 90.000 mm |

| Less diameter identified on piston crown | 89.960 mm |

| Thickness of the layer of graphite | 00.040 mm |

- The piston rings have been mounted with the greatest of care. Each time they are removed unnecessarily and refitted with excessive stretching, permanent deformation is caused and the operating performance is impaired.

- The piston pins are packed in a way that protects them from corrosion and they are enclosed with the piston, as are the pin locking devices (if required).

- The piston pins are selected for the appropriate fit and they can be exchanged within the same piston type. However, some of the pistons and pins are color coded. These parts may not be exchanged for others under any circumstances.

Assembly of piston and connecting rod

Prior to assembly, the con rods have been checked to see that their bores are on parallel axes (to ensure that there has been no bending or twisting), and if necessary, they have been replaced.

On assembly it must be ensured that the components are lubricated sufficiently. The pistons and con rods must always be assembled in the prescribed installation direction.

MAHLE Piston Identification Marks

These markings guarantee Quality MAHLE Pistons (on top of piston):

- Maker's quality sign

- Piston diameter in mm

Measured across the greatest skirt diameter (at the bottom of the skirt, perpendicular to the pin axis). On small pistons, mostly, only the measurement group and the nominal diameter are marked. Further information concerning the diameter as well as the fitting clearance are quoted on the package. - Standard or oversize dimensions in inches

On pistons for engines with cylinder dimensions in inches: "Std." or for example, ".020" for oversizes, in addition to the greatest piston diameter. - Fitting clearance in mm

Equivalent to the difference in diameter between the cylinder bore and the piston skirt at a temperature of 20'C (68'F). - Installation direction

The direction of installation in the form of a crankshaft flywheel symbol or an arrow showing the direction with respect to the control side of the engine. The marking "vorn", "Front" or "Abluft" (exhaust air) or a cast-in notch also indicates the installation direction, which must be considered not only because of an asymmetrical crown shape but also on account of the offsetting of the gudgeon hole for noise reasons. - Additional markings if necessary, e.g. A = Exhaust, E = Intake, 1 = Cylinder 1, Z 2/3 = Cylinders 2 and 3.

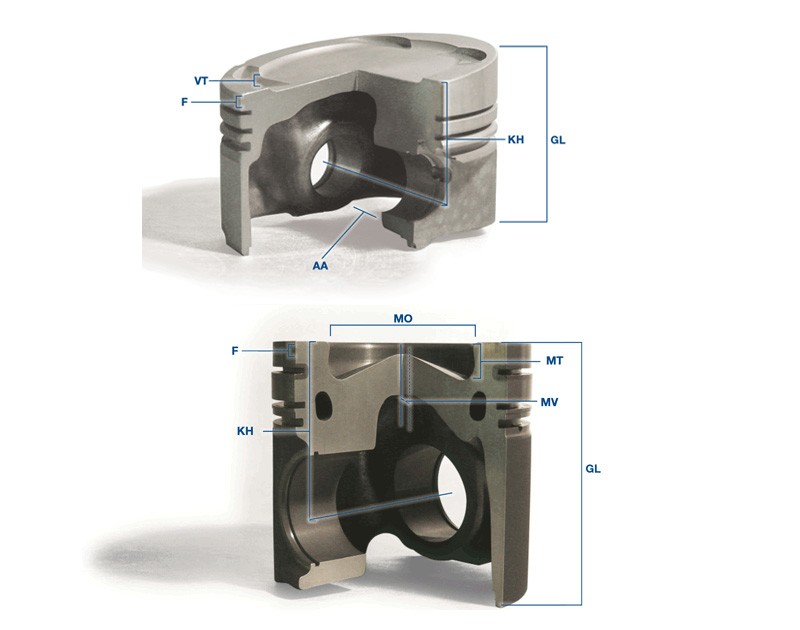

Main Piston Dimensions

Piston Dimensions

AA..... Distance between bosses

F...... Top land height

GL..... Total length

KH..... Compression height

MO..... Combustion chamber diameter

MT..... Combustion chamber depth

MV..... Combustion chamber offset

UH..... Dome height

VT..... Valve recess depth

MAHLE Piston Designs

Two-stroke These pistons are mainly used in gasoline and diesel engines for passenger cars under heavy load conditions. They have cast-in steel strips but are not slotted. As a result, they form a uniform body with extreme strength.

Cast solid skirt Piston top, ring belt and skirt form a robust unit. Cast solid skirt pistons have a long service life and can be used in gasoline and diesel engines. Their range of applications extends from model engines to large power units.

Forged solid skirt This type of piston can mainly be found in high performance series production and racing engines. Due to the manufacturing process, they are stronger and therefore allow reduced wall cross-sections and lower piston weight.

AUTOTHERMIK®- / HYDROTHERMIK® These very quiet running pistons are used primarily in passenger cars. The pistons have cast-in steel strips and are slotted at the transition from ring belt to skirt section.

AUTOTHERMATIK®- / HYDROTHERMATIK® These pistons are used mainly in gasoline and diesel engines for passenger cars under heavy load conditions. They have cast-in steel strips but are not slotted. As a result, they form a uniform body with extreme strength.

ECOFORM® pistons with pivoting side cores Weight optimized pistons for passenger car gasoline engines. As a result of a special casting technology these pistons offer low weight and high structural rigidity.

Ring carrier pistons with pin boss bushes These pistons for diesel engines have a ring carrier made from special cast iron that is connected metallically and rigidly with the piston material in order to make it more wear resistant, in particular in the first groove. With pin boss bushes made from a special material, the load-bearing capacity of the pin boss is increased.

Ring carrier pistons with cooling channel These pistons are used in conditions with particularly high operating temperatures. Because of the high temperatures at the piston top and the ring belt, intensive cooling is provided with oil circulating through the cooling channel.

Ring carrier pistons with cooling channel and crown reinforcement These pistons are used in diesel engines under heavy load conditions. For additional protection and to avoid cavity edge or crown fissures, these pistons have a special hard anodized layer (HA layer) on the crown.

Pistons with cooled ring carriers For these pistons, ring carriers and cooling channels are combined into one system in a special production process. This provides the pistons with significantly improved heat removal properties, especially in the first ring groove.

FERROTHERM® A steel piston top and an aluminum piston skirt that are flexibly connected via the gudgeon pin. Due to their high strength and lower wear values, these pistons make it possible to comply with low exhaust and emission standards, especially for diesel engines under heavy loads.