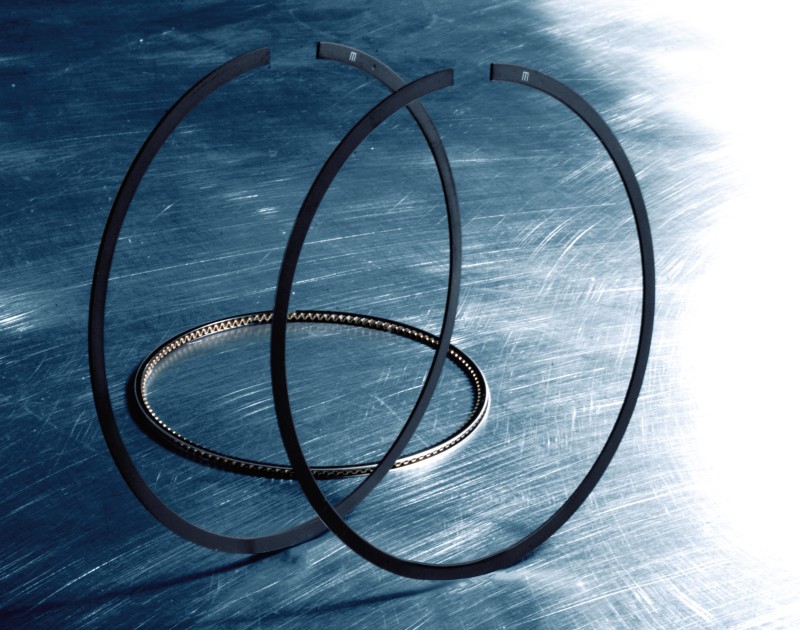

Performance Piston Rings

MAHLE is the largest piston ring manufacturer in the world, so it is no surprise that MAHLE Performance piston rings are the most extensively tested and technically advanced piston rings in the industry.

Current performance engines put a greater demand on piston rings than ever before, running at higher temperatures, cylinder pressures and higher operating RPM.

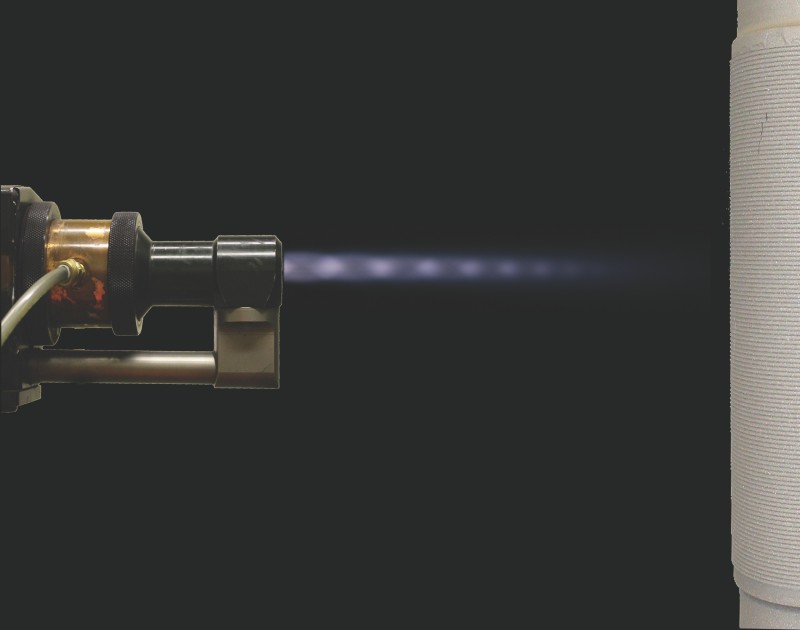

MAHLE has patented multiple designs and materials for performance piston rings, including HV385 Thermal Spray Face Coating, CP-20™ oil rings, and Fire-Power™ ring sets which exceed the ever increasing demands of todays most advanced performance engines and have set the high watermark for quality and innovation.

From off the shelf sets to individual rings and even custom finished rings, MAHLE Performance is the name race engineers worldwide turn to for reliability and performance.

- The combination of MAHLE's patented HV385 thermal spray face coating and SAE 9254 high alloy steel base material creates the ultimate in performance piston ring technology

- High tensile strength allows rings to stand up to extreme firing pressures

- Extended fatigue resistance increases cycle life and durability of the piston, increasing RPM expectations for high performance engines

- The second compression ring on a piston contributes significantly to engine performance by controlling oil migration and compression build up, especially in racing applications

- MAHLE's Tapered Hook Groove (THG) rings act as a check valve to relieve excess pressure build-up under the top ring, stabilizing and reducing the possibility of power loss

- THG second rings offer superior oil control when compared to traditional, reverse-twist, taper faced (RBT) rings

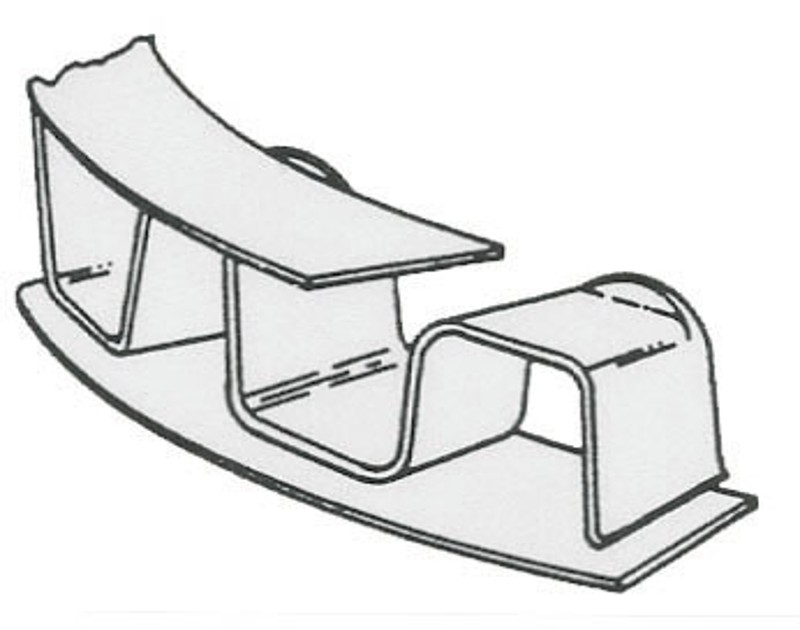

- MAHLE Performance CP-20™ oil rings utilize the exclusive 20° ear angle for the best possible side seal in the oil ring groove

- The exclusive ChemPolish™ process improves oil drain back

- The CP-20™ design simplifies installation, eliminating wire latches and nylon blocks, while the low deflection rate assures easy installation

- Each CP-20™ oil ring is designed around a specific bore diameter, providing the best possible oil control