ENGINE COOLING

Coolant cooler

Our coolant coolers are fundamental to the performance of an engine cooling module. Positioned in the air flow at the vehicle front, they’re able to optimally dissipate the waste engine heat, which is absorbed by the coolant, to the external air. All MAHLE components, such as the radiator core and water tank, including all connections and fastening elements, are carefully produced and offer a long service life. The radiator core itself is made up of the radiator network with a fin-and-tube system, the tube headers, and the core covers. In conventional radiators, the water tank is made of glass fiber-reinforced polyamide. All-aluminum radiators with reduced weight and a smaller packaging depth are also available.

Expansion tank

If the coolant temperature rises, it expands. This causes the pressure in the cooling tower to rise at the same time. To keep this pressure constant, MAHLE’s robust expansion tanks receive the expanding coolant via a valve located in the cap. In this way, they reliably ensure that the pressure is returned to the predefined level and the load on the cooling tower reduced.

Water pumps and kits

As a central element of a cooling circuit, water pumps are among the most sought-after spare parts. In order to fulfill market requirements, MAHLE offers conventional belt-driven pumps as well as electronically controlled models. Across the entire range, our water pumps are characterized by their high quality and fulfill all demands in terms of function and fit. They’re available not only as single parts (including O-belts and gaskets, if needed), but also as easy-to-assemble kits—with perfectly coordinated timing belts and, if required, tension, deflection, and guide rollers as well as gaskets and dampers.

Cabin heat exchanger

MAHLE cabin heat exchangers use the waste engine heat for temperature management in the vehicle cabin. The principle is as simple as it is effective: Coolant flows through the heat exchangers located under the dashboard. The air flow generated by the interior blower moves past the heat exchangers and is heated up. This heat is emitted directly into the passenger cabin and ensures a comfortable climate when it’s cold outside.

Condenser/Radiator fan

Efficient engine cooling requires not only powerful radiators but also high-performance fans, such as those available from MAHLE. They comprise an electric motor with a flanged fan wheel. They’re installed upstream or downstream of the condenser or radiator and reliably extract the heat from the coolant by means of their air flow. Cars with air conditioning require an additional or correspondingly more powerful fan.

Fans and fan drives

Providing cooling air in an efficient way reduces fuel consumption and lowers the impact on the environment. With the products from our traditional Visco® brand, which has been around for more than 50 years, MAHLE offers a range of highly proven and powerful fans and fan drives. The Visco® fan drives generate additional savings and reduce engine noise. In commercial vehicle engines and powerful passenger car engines, they enable on-demand control of the cooling air flows by creating a frictional connection to the fan wheel—depending on the temperature—and influencing its speed. If no cooling air is needed, the fan drive switches off completely.

Oil cooler

With technologically advanced oil coolers from MAHLE, not only are oil change intervals longer, but, thanks to the almost constant temperature spectrum of the engine oil, the engine’s service life is also increased. To fulfill all of our customers’ demands, we offer a wide selection of air- and coolant-cooled oil cooler types. The variable stacked-plate oil cooler features a particularly lightweight, space-saving, all-aluminum design with no coolant housing.

Charge air cooler

From the performance increase across the whole rpm range to fuel savings and a lowering of the thermal load on the engine: cooling the combustion air in turbocharged engines with a charge air cooler offers numerous advantages. So, it’s no surprise that almost all modern motor vehicles with turbochargers are equipped with this technology. MAHLE offers two different variants: models for direct charge air cooling, in which the cooler—fitted in the vehicle’s front end—is cooled via the ambient air as well as models with indirect charge air cooling. These models make use of coolants and dissipate the heat to the ambient air via a low-temperature radiator.

Exhaust gas recirculation cooler

The combustion temperature in the cylinder plays a significant role in the formation of nitrogen oxides in the combustion chamber. MAHLE exhaust gas recirculation coolers make it possible to reliably comply with the prescribed limit values. Special heat exchangers made of high-grade stainless steel or aluminum quickly cool part of the main exhaust gas flow. This is then fed back into the intake air. The lower combustion temperature in the cylinder has a positive impact on the formation of NOx.

AIR CONDITIONING

A/C compressors

With the acquisition of the thermal management activities from Delphi Automotive PLC and the recent integration of the air conditioning compressor product group into the MAHLE Group, MAHLE has further expanded its leading position as an original equipment manufacturer. When it comes to vehicle cooling and climate control MAHLE is the competent technology-partner for all leading OE-manufacturers.

A/C condenser

The A/C condenser is the counterpart to the A/C compressor: The latter compresses and heats the refrigerant, while the condenser reduces the temperature again. To this end, the gas flows through the pipework and fins of the A/C condenser installed upstream of the coolant cooler, thereby emitting heat. This lowers the pressure and causes the refrigerant to liquefy. To facilitate logistics and assembly, MAHLE’s range not only includes numerous A/C condensers but also finished modules. These are ready-made units comprising a flat-tube condenser and the collection/expansion tank with integrated drier.

Filter-drier and accumulator

If the refrigerant is contaminated or contains moisture, this may damage the compressor and other components. The carefully produced MAHLE filter-driers, which—depending on the system—are also called accumulators, prevent this: the liquid refrigerant flows through this component and passes through a hygroscopic filter, which retains both moisture and fine particles. However, as the filter-drier can only absorb a limited amount of moisture before the drying medium becomes saturated, it must be replaced regularly—every two years or every time the refrigerant circuit is opened. Filter-driers from MAHLE also fulfill another important task: their top section serves as a compensation chamber, while the lower section acts as a refrigerant store. This compensates pressure fluctuations in the system in an optimal way.

Expansion valve and orifice tube

The expansion valve—or, depending on the design of the air conditioning system, the orifice tube—is located upstream of the evaporator and separates the high- and low-pressure areas in the refrigerant circuit. The liquid refrigerant is injected into the evaporator via the valve, where it is converted into gas, producing the required evaporation cooling. To achieve optimal cooling performance, MAHLE expansion valves or orifice tubes regulate the refrigerant flow precisely as needed.

Evaporator

The evaporator is a core element of temperature management. It is located in the vehicle cabin below the dashboard and is integrated into the ventilation system. The evaporator takes care of the heat transfer between the surrounding air and the refrigerant in the air conditioning. Under high pressure, the liquid refrigerant transforms into a gaseous state. The evaporation cooling generated by this process is then dissipated into the environment via the large surface of the evaporator and routed directly into the vehicle cabin by the blower’s air flow. MAHLE evaporators are characterized by their high performance, small packaging depth, and low weight.

Interior blower

Providing a clear view and pleasant climate inside the vehicle, interior blowers from MAHLE not only play a significant role in terms of comfort, but also for the safety of drivers and front-seat passengers. That’s why it’s so important that they’re produced carefully—to ensure a long service life.

A/C switch

MAHLE A/C switches reliably control various shunt relays and are responsible for switching individual systems components on and off at specified pressure points. This means that the air conditioning can be used safely and effectively at all times and in any conditions.

A/C blower control unit and resistor

Blower control units regulate the blower fan and thus the air flow in the passenger cabin. They’re often located near the interior blower or installed directly on the fan. MAHLE offers a number of different control unit variants that work either electrically or electronically.

The electric blower control units have several resistors and, in most cases, an integrated thermal fuse—in case of overload, they’re switched off to protect other components. The electric control units allow the fan to be operated at different speeds.

The electronic blower control units from MAHLE are controlled via a pulse-width-modulated signal. Air conditioning can thus be adjusted thanks to a convenient and continuously variable fan. Another advantage is the integrated self-diagnose: they can determine their own state and report any errors immediately to the control unit.

Electric control for blending flap

Electrically driven controls for MAHLE air conditioning systems fulfill even the most stringent demands: they’re primarily used in automatically controlled air conditioning systems to control air flaps or mixing flaps. In this way, they ensure optimal distribution of the air flow within the vehicle cabin. This decreases the risk of windows fogging or freezing up, or of the driver’s concentration being hampered by an uncomfortable cabin climate or air draft.

A/C compressor oils

The quality of the A/C compressor oils used is crucial for ensuring that the air conditioning can be used safely and for a long time. The use of low-grade or incorrect oil results in increased wear and may lead to premature failure of the A/C compressor. MAHLE offers a range of synthetic compressor oils. We particularly recommend the PAO 68 oil, which has been used effectively for more than 20 years and helps increase the performance of the air conditioning system. In contrast to other oils, PAO 68 is not hygroscopic—i.e., it does not absorb any moisture from the ambient air. It can replace various PAG oils and can be used in air conditioning systems with R134a and, in some cases, R1234yf. Sometimes it is also found in electrically driven A/C compressors (please see the relevant usage overview). This makes handling significantly easier: for most applications, a version of the PAO 68 oil is sufficient. The full warranty applies to A/C compressors from MAHLE running on PAO 68 oil as well as PAO 68 Plus UV oil.

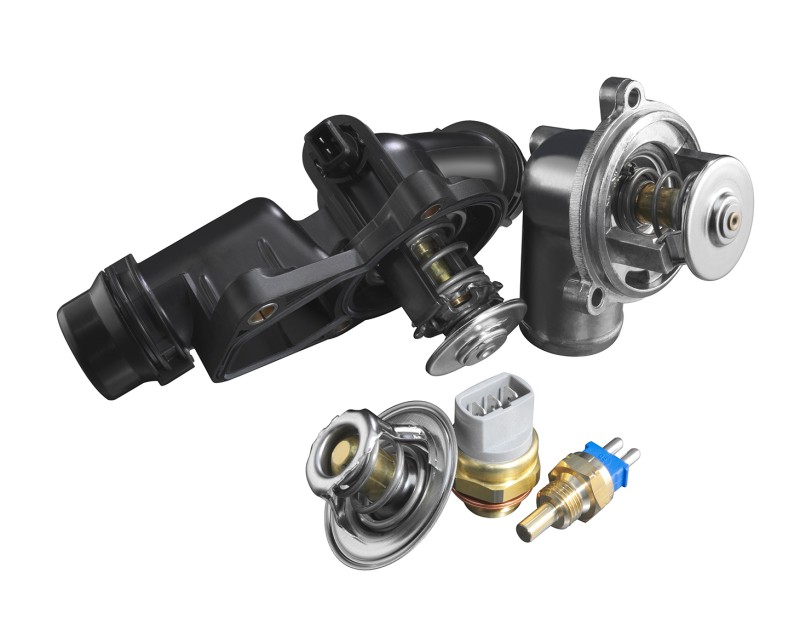

Thermostats

As a global partner, MAHLE develops and produces thermal management systems and components for well-known automobile and engine manufacturers.

MAHLE thermostats work just as well in tropical heat as in arctic cold. They quickly bring each engine to the correct operating temperature by controlling the cooling circuit. MAHLE provides a variety of thermostats and other temperature-regulating components for various requirements.

MAHLE expands thermal management portfolio

Following the acquisition of the entire shareholding in Behr Hella Service (BHS) by MAHLE Aftermarket, all existing activities of BHS will be transferred to MAHLE on January 1, 2020. For MAHLE customers, this means access to a broad portfolio of thermal management products for passenger cars and trucks as well as agricultural vehicles and construction machines. In the future, products will be offered under the BEHR sales brand and the portfolio continuously expanded.

The following products will complement the product range starting in 2020:

Air conditioning

- A/C condensers

- Filter-driers and accumulators

- Expansion valves and orifice tubes

- Evaporators

- A/C switches

- Electric controls for blending flaps

- Interior blowers

- A/C compressor oils

- A/C blower regulators and resistors

- A/C compressors

Engine cooling

- Coolant coolers

- Expansion tanks

- Visco® fan drives/fan clutches

- Coolant cooler/condenser fans

- Charge air coolers

- Oil coolers

- Cabin heat exchangers

- Exhaust gas recirculation coolers

- Water pumps and kits

- Switches and sensors