Performance Engine Bearings

MAHLE Performance boasts the most extensive line of performance engine bearings in the market hands down. Combining the legendary CLEVITE bearing brand for domestic applications with the global coverage in the MAHLE brand for the import market, MAHLE Performance truly is the engine bearing of choice in the performance bearing market.

CLEVITE engine bearings have been winning NASCAR sanctioned races since the very first NASCAR championship in 1948 and have powered every single NASCAR champion since then to Victory Lane, setting the pace for quality and reliability in the most demanding settings.

Whether modifying stock engines or building race engines from the ground up, the legacy of excellence that began decades ago, continues today with MAHLE Performance and CLEVITE engine bearings.

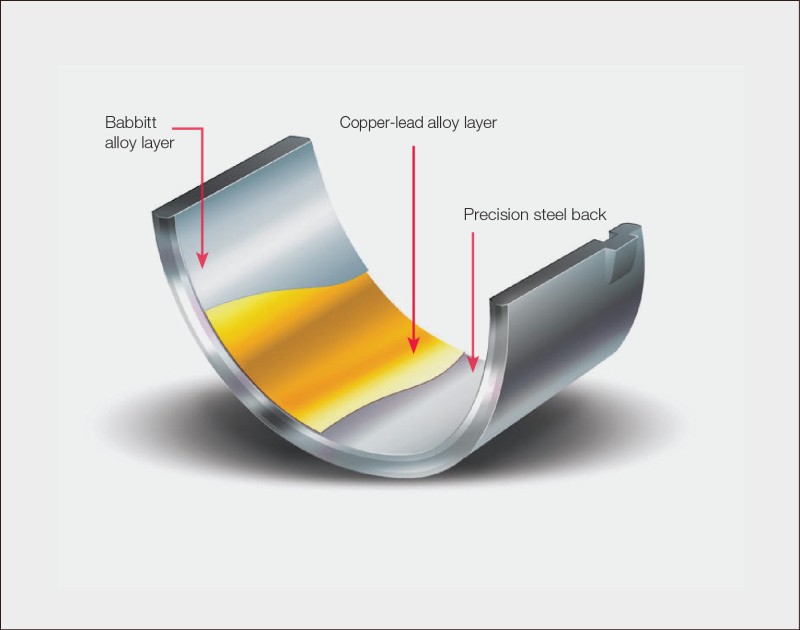

TriMetal™ Engine Bearings

- Exclusive three layer design capable of carrying max loads of up to 12,000 psi

- Copper-lead alloy layer, precision steel back layer and electroplated white metal "babbitt" surface layer reduces drag and increases horsepower

- Withstands up to 60% higher loads

- 40% better seizure resistance than the competition

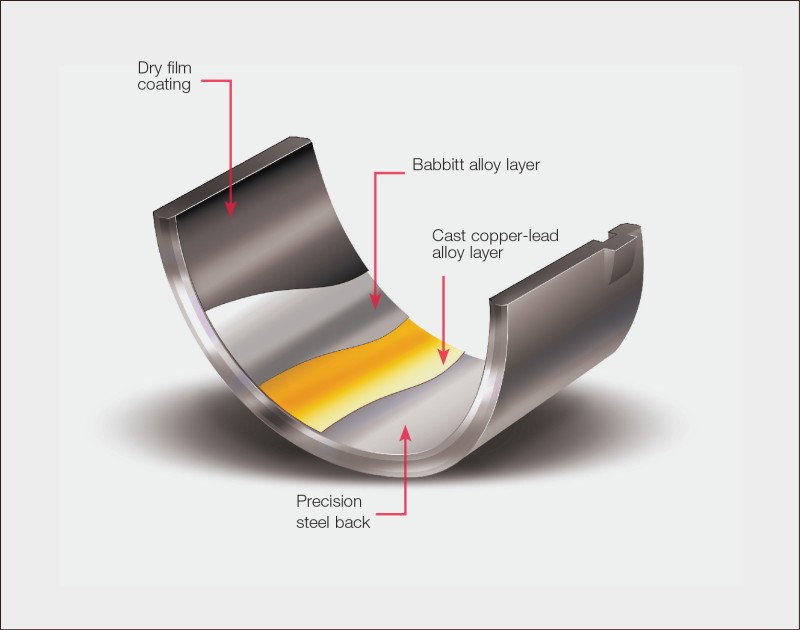

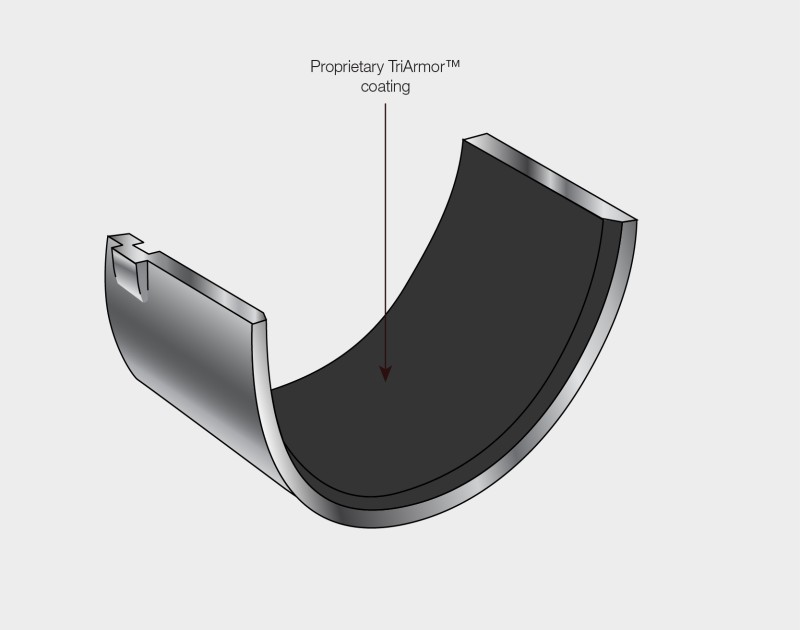

TriArmor™ Coated Engine Bearings

- Exclusive TriArmor™ bearings combine TriMetal™ technology with the industry's only moly/graphite, high pressure, high load, dry film treatment for engine bearings, providing additional protection across a broad range of operating temperatures

- Low friction PTFE polymer base offers extraordinary protection and lubricity

- Increases bearing life in race engines and street engines

Our engine bearings are offered in five series to tailor to your specific needs, each series identified by a letter: H, C, F, V and M:

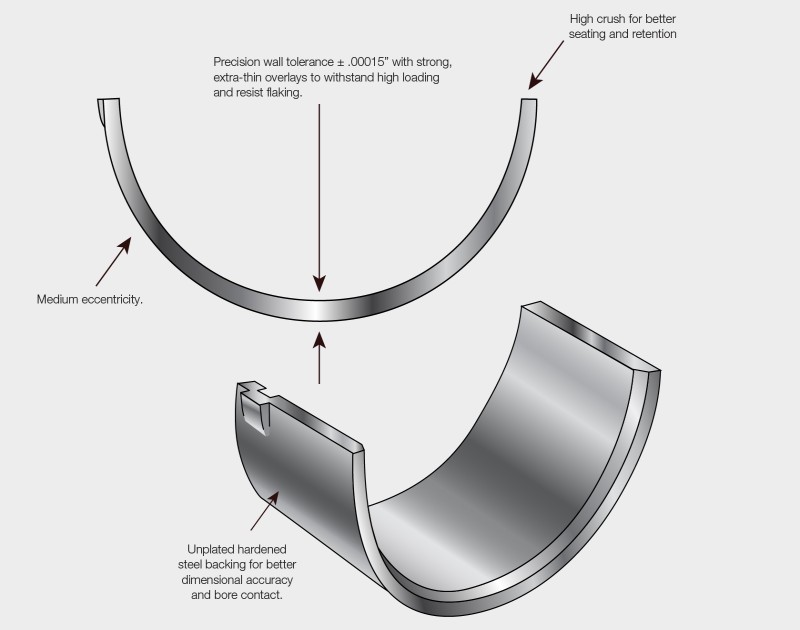

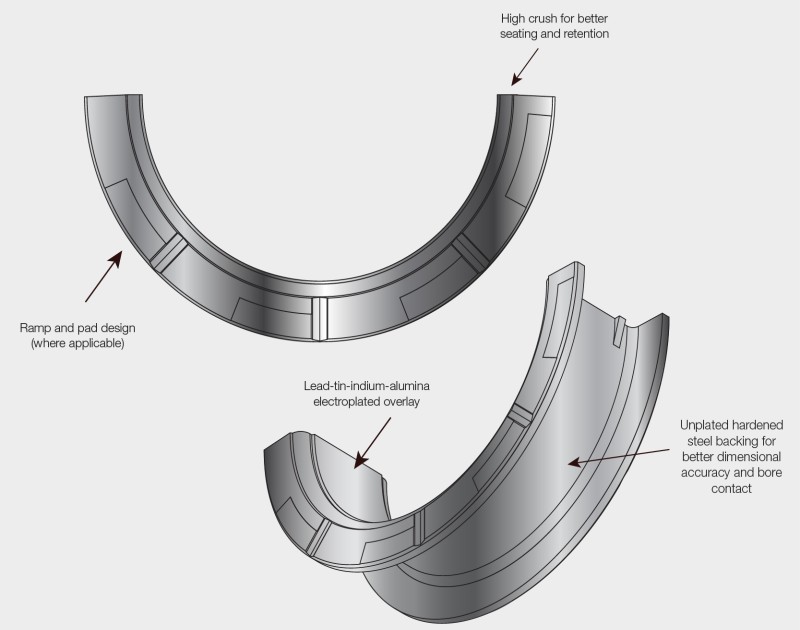

- H-Series bearings were developed primarily for use in NASCAR type racing, but are suitable for all types of competition engines

- Medium level of eccentricity, high crush and rod bearings have a hardened, steel back and thin overlay

- Made without flash plating for better seating

- If you aren't sure which type of performance bearing to start with, the H-Series bearing will be your best choice

- C-Series bearings were developed primarily for high performance applications and all types of competition engines

- Feature MAHLE's TriArmor™ face coating, a proprietary .0003" dry film treatment applied to the bearings surface that provides great low load start-up protection and extended engine life

- These TriArmor™ bearings offer the strength and durability of the legendary CLEVITE TriMetal™ bearing construction coupled with the latest in coating technology

- Testing has shown a 126% increase in load carrying capacity before seizure vs conventional copper/tin/lead overlay bearings

- Increased fatigue strength & wear resistance overlay

- 93% thrust load increase versus flat pad thrust design (when applicable

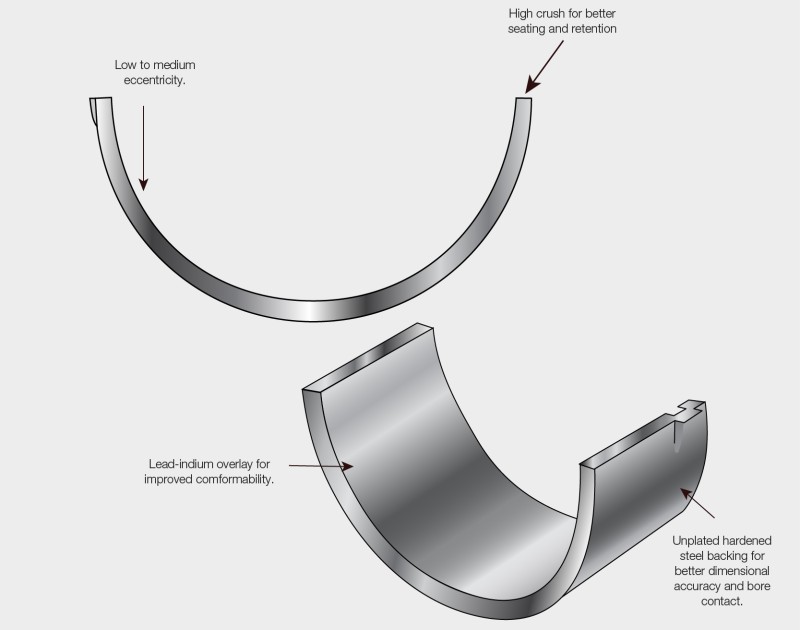

- V-Series rod bearings typically have low to medium eccentricity and a hardened steel back

- Do not have flash plating on the steel back

- Use a lead-indium overlay which offers better conformability than lead-tin copper overlay with slightly reduced wear resistance

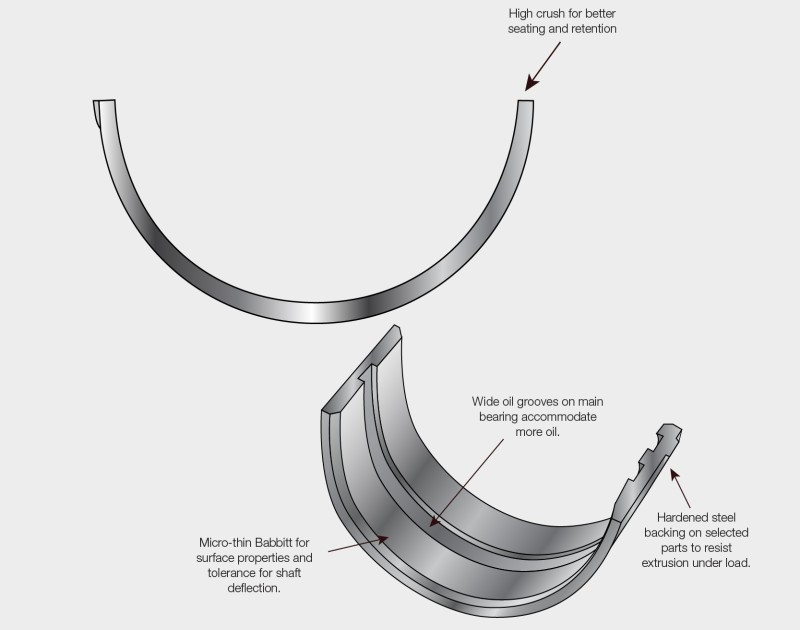

- "Micro" bearings make up the M-series and are intended mainly for engines where severe crankshaft deflections cause edge loading of the bearings

- Special purpose bearings have a nominal .006" thick babbitt lining on a hardened steel back

- Use M-Series parts to take advantage of the high degree of conformability offered by the babbitt lining