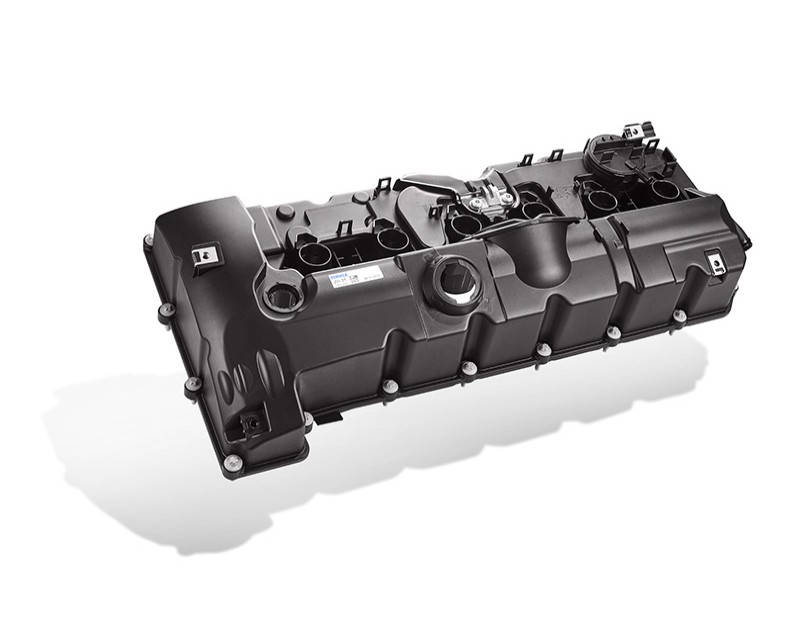

Cylinder head cover / valve cover

Cylinder head covers close off the cylinder head and generally form the upper closure of an internal combustion engine. To optimize costs and weight, they are usually made of highly stable thermoplastics material. However, there are also hybrid hoods made from a combination of thermoplastics material and aluminum. Cylinder head covers have to meet stringent requirements in terms of engine acoustics and leak tightness. As a visible component, however, they also fulfill a certain design requirement.

But cylinder head covers can do even more: Modern designs integrate further components such as oil mist separators, pressure-regulating valves, check valves or vacuum tanks. They also perform additional functions such as fixing ignition cables and fuel lines, the wire harness and the oil filler tube. This integration in one assembly makes cylinder head covers a technically and geometrically complex product that must withstand high loads and temperatures over a long running time.

Air intake module

With increasing emissions regulations and lower fuel consumption requirements, combustion engines must become ever more efficient and cleaner. Air intake modules play an important role in modern and complex combustion engines. They perform far more functions than just filtering and distributing the air volume across the cylinders. For example, MAHLE has taken a major development step for the modern combustion engine by integrating charge air cooling into the air intake module.

An air intake system from MAHLE results in a clean, even, and low-resistance air flow for better performance and lower consumption. At the same time, air intake modules have to withstand ever higher temperatures and optimize acoustics—and all this with less and less available installation space under the hood.

Oil mist separator

Most oil mist separators are integrated into the cylinder head cover. They separate gaseous and liquid components from the oil mist found in the crankcase ventilation system. The separated oil is returned to the oil circuit and the residual air to the intake system. Oil mist separators must have a very high separation level because engines with exhaust gas turbochargers are particularly sensitive to oil components in the exhaust gas. This makes oil mist separators an important component in compliance with the strict exhaust emission standards.

Oil filter module / oil filter cover

In most cases, the oil filter module is flange-mounted directly to the engine block. High-performance plastics and aluminum pressure die-casting elements are used for the housing—for high stability and low component weight. In addition to filtering and cooling the oil in gasoline and diesel engines, oil filter modules perform many other functions in modern vehicles. These include optional oil mist separation, sensor technology for pressure and temperature control, regulation for oil pressure and crankcase pressure regulation or, for example, thermostat-controlled regulation of the oil flow to the heat exchanger. Modern oil filter modules are flow-optimized and thus help to increase the efficiency of the engine.