Chrysler

Mitsubishi 3.0L Intake Manifold Gaskets (SS-GA-C-02)

ISSUE:

Some Chrysler and Mitsubishi vehicles with 3.0L engines tend to develop coolant leaks in the lifter valley of the intake manifold gasket. These leaks occur because of the thermal expansion and contraction of the block and cylinder head during engine operation.

RESOLUTION:

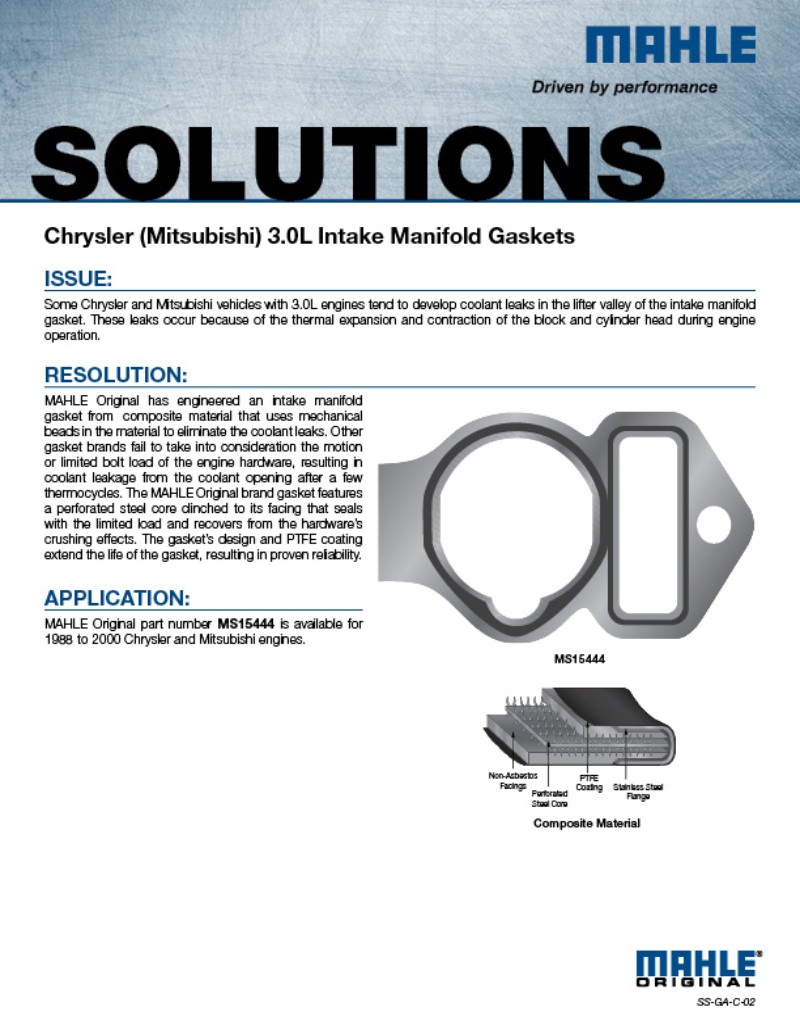

MAHLE Original has engineered an intake manifold gasket from composite material that uses mechanical beads in the material to eliminate the coolant leaks. Other gasket brands fail to take into consideration the motion or limited bolt load of the engine hardware, resulting in coolant leakage from the coolant opening after a few thermocycles. The MAHLE Original brand gasket features a perforated steel core clinched to its facing that seals with the limited load and recovers from the hardware’s crushing effects. The gasket’s design and Teflon® coating extend the life of the gasket, resulting in proven reliability.

APPLICATION:

MAHLE Original part number MS15444 is available for 1988 to 2000 Chrysler and Mitsubishi engines.

Download PDF [PDF; 343 KB]

Dodge Ram / Cummins “B-Series” 5.9L Head Gasket (SS-GA-C-03)

ISSUE:

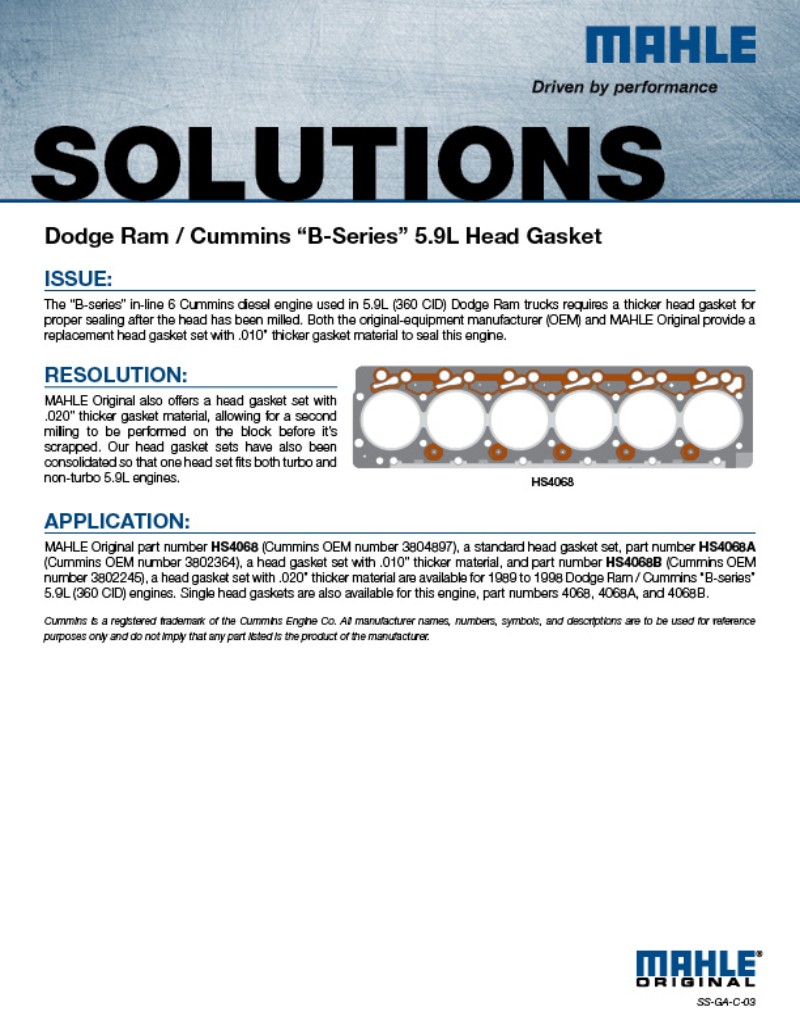

The “B-series” in-line 6 Cummins diesel engine used in 5.9L (360 CID) Dodge Ram trucks requires a thicker head gasket for proper sealing after the head has been milled. Both the original-equipment manufacturer (OEM) and MAHLE Original provides a replacement head gasket set with .010” thicker gasket material to seal this engine.

RESOLUTION:

MAHLE Original also offers a head gasket set with .020” thicker gasket material, allowing for a second milling to be performed on the block before it’s scrapped. Our head gasket sets have also been consolidated so that one head set fits both turbo and non-turbo 5.9L engines.

APPLICATION:

MAHLE Original part number HS4068 (Cummins OEM number 3804897), a standard head gasket set, part number HS4068A (Cummins OEM number 3802364), a head gasket set with .010” thicker material, and part number HS4068B (Cummins OEM number 3802245), a head gasket set with .020” thicker material are available for 1989 to 1998 Dodge Ram / Cummins “B-series” 5.9L (360 CID) engines. Single head gaskets are also available for this engine, part numbers 4068, 4068A, and 4068B.

Download PDF [PDF; 313 KB]

5.7L HEMI® Cylinder Head Gasket (SS-GA-C-04)

ISSUE:

The 5.7L HEMI OE head gasket will not accommodate a larger piston/bore combination that may be needed for proper rebuilding of the engine. OE and Aftermarket competitors offer multiple part numbers rather than one consolidated gasket that fits all.

RESOLUTION:

The latest MAHLE Original 5.7L HEMI head gasket is a consolidated design fitting both 2003-2008 and 2009-2014 5.7L HEMI engines covering over 2.4 million vehicles in operation. The consolidated gasket is tailored to engine rebuilders by accommodating a 0.030 inch overbore with the thicker option allowing for cylinder head/cylinder block resurfacing. The MAHLE Original standard gasket and thicker option provide rebuilders with the greatest flexibility in block/deck, cylinder head, and cylinder bore corrections.

For ease of use, both gasket thicknesses are designed to work with all model years – no need to stock two different gaskets depending on the year of engine.

54417A (R/H) & 54418A (L/H):

- 3 layer: Fully rubber (Fluoroelastomer) coated embossed stainless steel outer layers with stainless steel inner layer

- Compressed operating thickness: .70mm / .0275in

- Designed to accommodate 0.030in overbore pistons

54417B (R/H) & 54418B (L/H):

- 4 layer: Fully rubber (Fluoroelastomer) coated embossed stainless steel outer layers with stainless steel inner layers

- Compressed operating thickness: .90mm / .0355in

0.0086in thicker than the 03–08 OE head gaskets

0.0125in thicker than the 09–14 OE head gaskets - Designed to accommodate 0.030in overbore pistons

APPLICATION:

Both the three and four layer MAHLE Original gaskets fit the 2003-2014 5.7L HEMI engine.

- MAHLE Original part numbers 54417A and 544418A are for the 3-layer gasket (Standard thickness)

- MAHLE Original part numbers 54417B and 54418B are for the 4-layer gasket (Thicker option)

Download PDF [PDF; 475 KB]

Saturn VUE 3.0L Intake Manifold Set (SS-GA-G-26)

ISSUE:

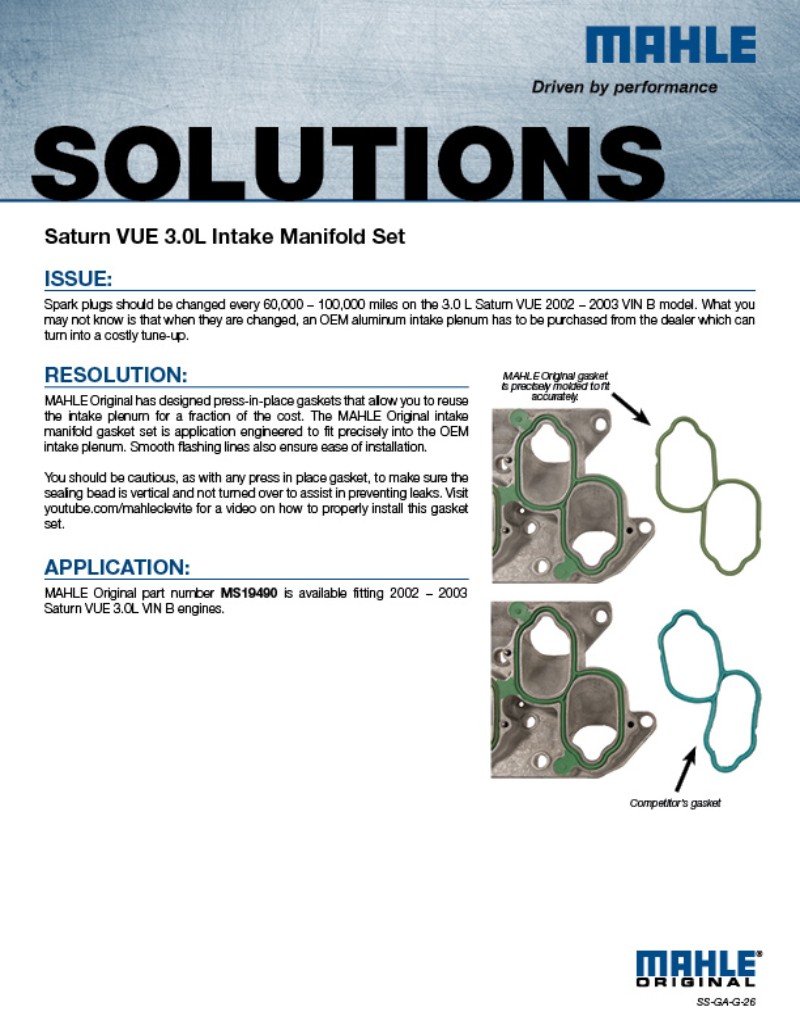

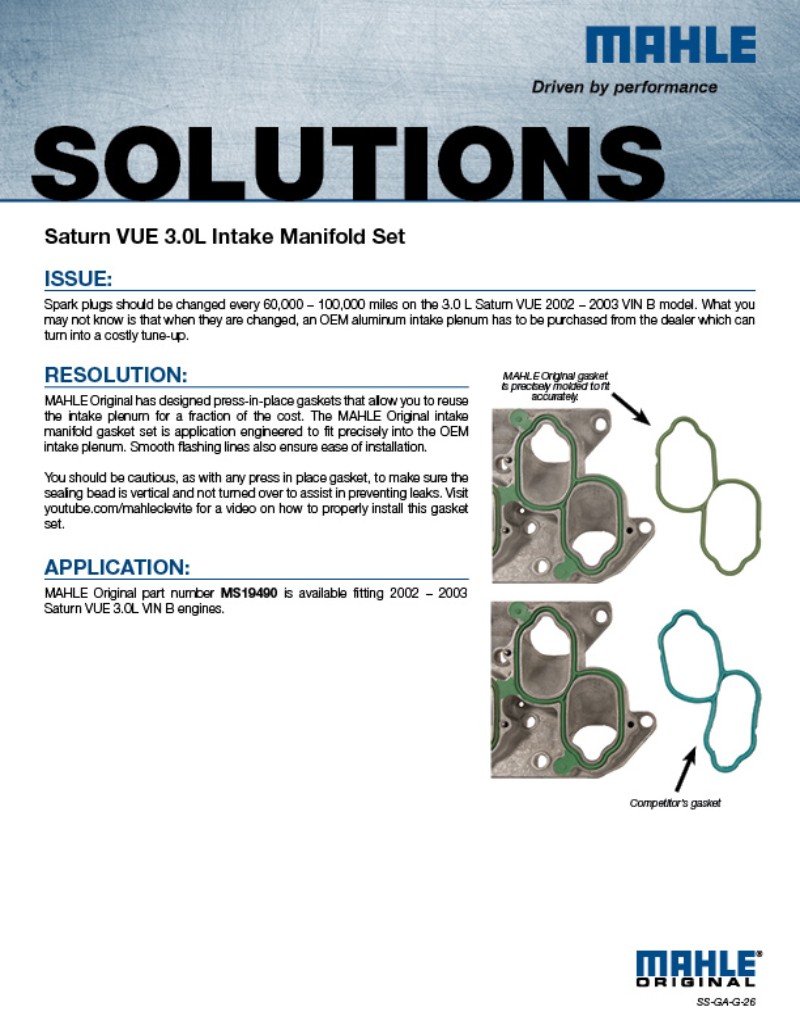

Spark plugs should be changed every 60,000 – 100,000 miles on the 3.0 L Saturn VUE 2002 – 2003 VIN B model. What you may not know is that when they are changed, an OEM aluminum intake plenum has to be purchased from the dealer which can turn into a costly tune-up.

RESOLUTION:

MAHLE Original has designed press-in-place gaskets that allow you to reuse the intake plenum for a fraction of the cost. The MAHLE Original intake manifold gasket set is application engineered to fit precisely into the OEM intake plenum. Smooth flashing lines also ensure ease of installation.

You should be cautious, as with any press in place gasket, to make sure the sealing bead is vertical and not turned over to assist in preventing leaks. Visit youtube.com/mahleclevite for a video on how to properly install this gasket set.

APPLICATION:

MAHLE Original part number MS19490 is available fitting 2002 – 2003 Saturn VUE 3.0L VIN B engines.

Download PDF [PDF; 647 KB]

Ford

Small Block V-8 Head Gasket (SS-GA-F-01)

ISSUE:

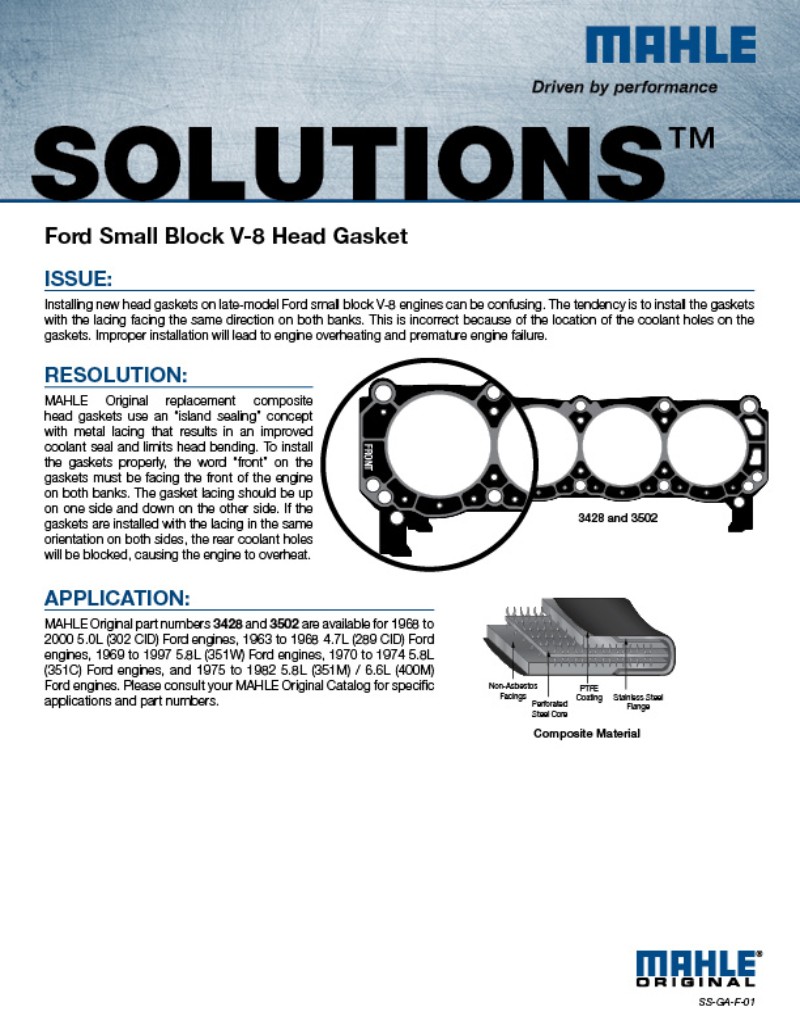

Installing new head gaskets on late-model Ford small block V-8 engines can be confusing. The tendency is to install the gaskets with the lacing facing the same direction on both banks. This is incorrect because of the location of the coolant holes on the gaskets. Improper installation will lead to engine overheating and premature engine failure.

RESOLUTION:

MAHLE Original replacement composite head gaskets use an “island sealing” concept with metal lacing that results in an improved coolant seal and limits head bending. To install the gaskets properly, the word “front” on the gaskets must be facing the front of the engine on both banks. The gasket lacing should be up on one side and down on the other side. If the gaskets are installed with the lacing in the same orientation on both sides, the rear coolant holes will be blocked, causing the engine to overheat.

APPLICATION:

MAHLE Original part numbers 3428 and 3502 are available for 1968 to 2000 5.0L (302 CID) Ford engines, 1963 to 1968 4.7L (289 CID) Ford engines, 1969 to 1997 5.8L (351W) Ford engines, 1970 to 1974 5.8L (351C) Ford engines, and 1975 to 1982 5.8L (351M) / 6.6L (400M) Ford engines. Please consult your MAHLE Original Catalog for specific applications and part numbers.

Download PDF [PDF; 360 KB]

Escort 1.6L and 1.9L Cylinder Head Gaskets (SS-GA-F-05)

ISSUE:

Ford uses a two-millimeter thick head gasket on 1981 to 1985 1.6L (98 CID) engines and 1985 to 1996 1.9L engines to avoid piston-to-valve interference. Some replacement gasket manufacturers use additional facing material to achieve the correct gauge. This can make the gasket excessively soft, resulting in torque loss and gasket failure.

RESOLUTION:

MAHLE Original offers a head gasket manufactured from material that uses a unique combination of graphite and three steel cores to increase core size while minimizing the facing thickness. This gasket restores the original-equipment operating thickness, resulting in minimum torque loss while maintaining the balance of the combustion and coolant seals.

APPLICATION:

MAHLE Original part number 5739 is available for 1981 to 1985 Ford 1.6L (98 CID) engines and 1985 to 1990 Ford 1.9L (116 CID) engines, and part number 5884 is available for 1991 to 1996 Ford 1.9L (116 CID) engines.

Download PDF [PDF; 305 KB]

3.0L OHV V6 Oil Pan Gaskets (SS-GA-F-11)

ISSUE:

Ford 3.0L OHV V6 “Vulcan” engines manufactured between March 27, 1990 and 2001, and used in the Ford Taurus and Mercury Sable, have problems with the original-equipment (OE) oil pan gaskets leaking.

RESOLUTION:

MAHLE Original offers an improved molded rubber replacement oil pan gasket for the Ford 3.0L OHV V6 “Vulcan” engine that is superior to the OE floppy gasket design. The molded rubber gasket is comprised of molded silicone rubber applied to a plastic carrier with metal load limiters to extend service life. The gasket also includes four tabs that attach to the oil pan, allowing for easy installation and eliminating the need for an adhesive.

APPLICATION:

MAHLE Original part number OS32486 is available for March 27, 1990 to 2001 and OS32251 is available for 2002-2008 Ford 3.0L OHV V6 engines. The gasket set includes the gasket, 16 new fasteners, sealant, and detailed installation instructions.

Download PDF [PDF; 343 KB]

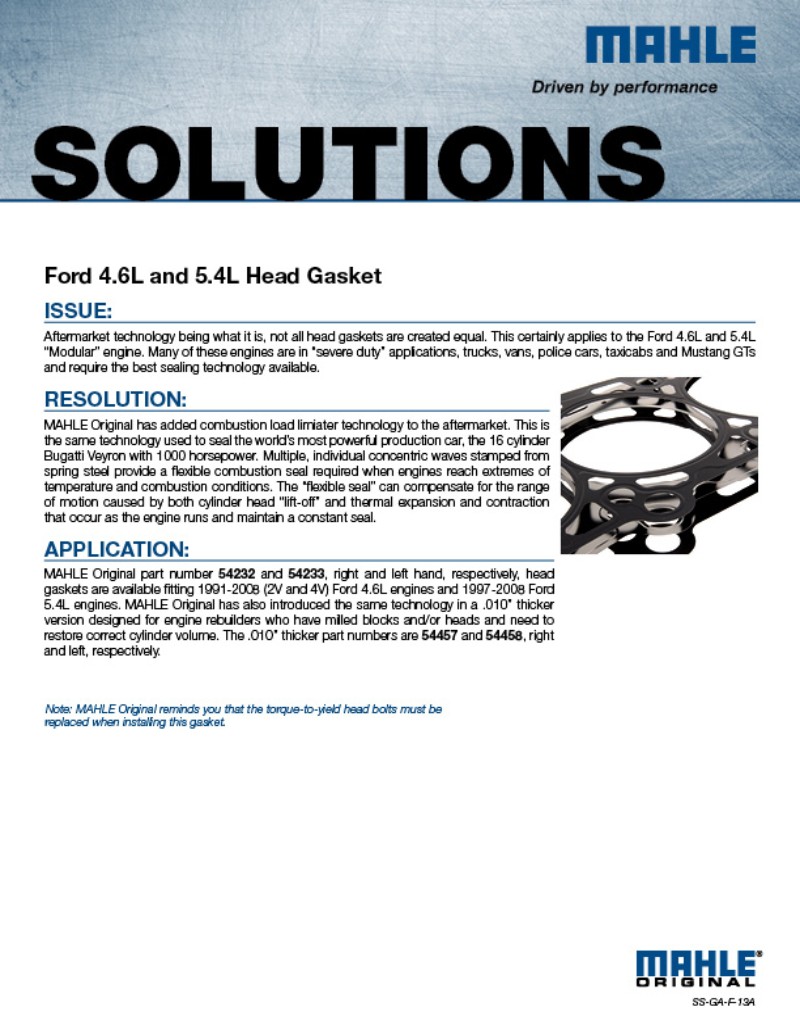

4.6L and 5.4L Head Gasket (SS-GA-F-13A)

ISSUE:

Aftermarket technology being what it is, not all head gaskets are created equal. This certainly applies to the Ford 4.6L and 5.4L “Modular” engine. Many of these engines are in “severe duty” applications, trucks, vans, police cars, taxicabs and Mustang GTs and require the best sealing technology available.

RESOLUTION:

MAHLE Original has added combustion load limiter technology to the aftermarket. This is the same technology used to seal the world’s most powerful production car, the 16 cylinder Bugatti Veyron with 1000 horsepower. Multiple, individual concentric waves stamped from spring steel provide a flexible combustion seal required when engines reach extremes of temperature and combustion conditions. The “flexible seal” can compensate for the range of motion caused by both cylinder head “lift-off” and thermal expansion and contraction that occur as the engine runs and maintain a constant seal.

APPLICATION:

MAHLE Original part number 54232 and 54233, right and left hand, respectively, head gaskets are available fitting 1991-2008 (2V and 4V) Ford 4.6L engines and 1997-2008 Ford 5.4L engines. MAHLE Original has also introduced the same technology in a .010” thicker version designed for engine rebuilders who have milled blocks and/or heads and need to restore correct cylinder volume. The .010” thicker part numbers are 54457 and 54458, right and left, respectively.

Download PDF [PDF; 464 KB]

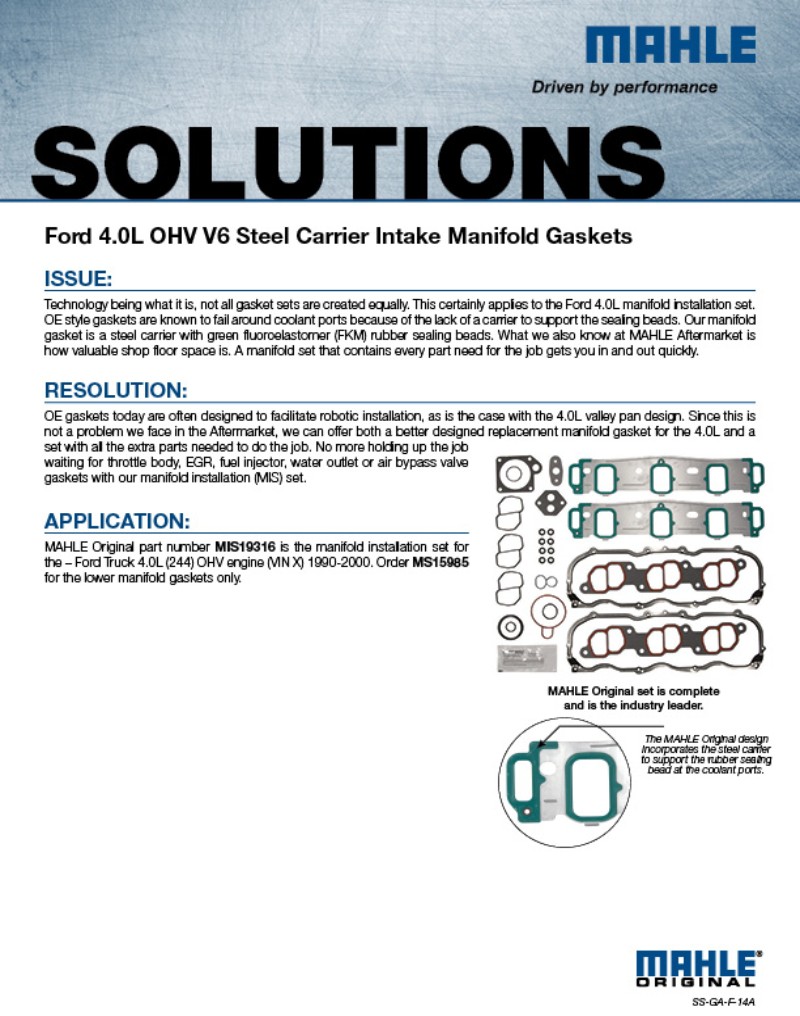

4.0L OHV V6 Steel Carrier Intake Manifold Gaskets (SS-GA-F-14A)

ISSUE:

Technology being what it is, not all gasket sets are created equally. This certainly applies to the Ford 4.0L manifold installation set. OE style gaskets are known to fail around coolant ports because of the lack of a carrier to support the sealing beads. Our manifold gasket is a steel carrier with green fluoroelastomer (FKM) rubber sealing beads. What we also know at MAHLE Original is how valuable shop floor space is. A manifold set that contains every part need for the job gets you in and out quickly.

RESOLUTION:

OE gaskets today are often designed to facilitate robotic installation, as is the case with the 4.0L valley pan design. Since this is not a problem we face in the Aftermarket, we can offer both a better designed replacement manifold gasket for the 4.0L and a set with all the extra parts needed to do the job. No more holding up the job waiting for throttle body, EGR, fuel injector, water outlet or air bypass valve gaskets with our manifold installation (MIS) set.

APPLICATION:

MAHLE Original part number MIS19316 is the manifold installation set for the – Ford Truck 4.0L (244) OHV engine (VIN X) 1990-2000. Order MS15985 for the lower manifold gaskets only.

Download PDF [PDF; 645 KB]

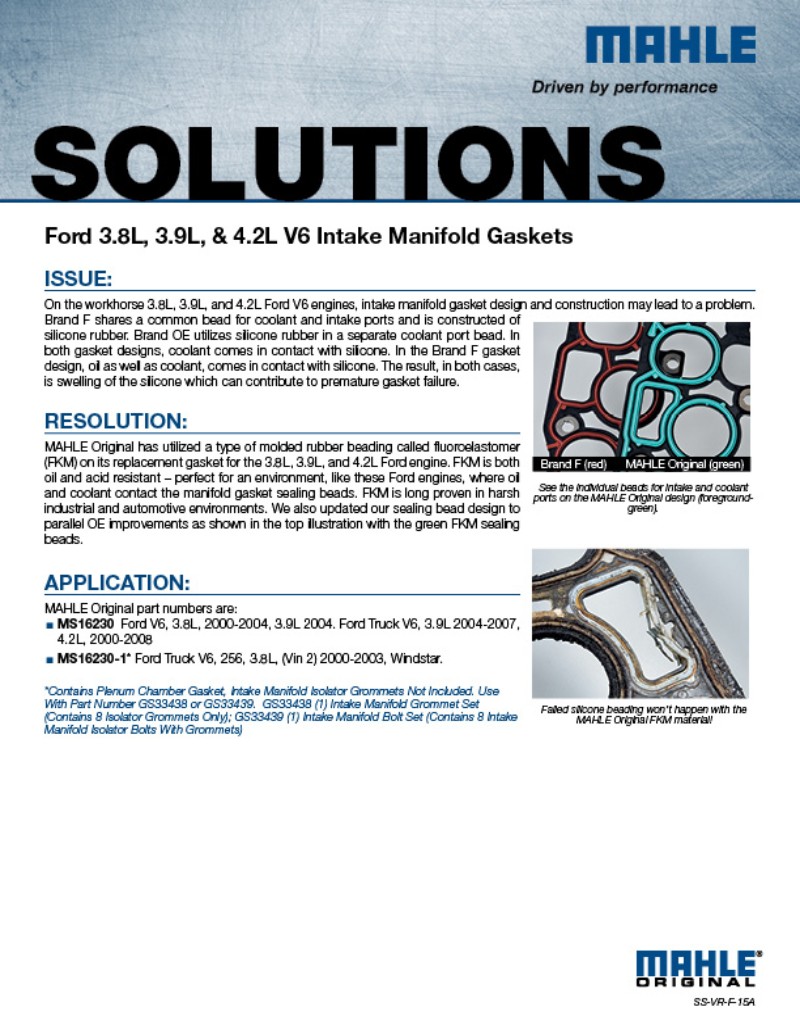

3.8L, 3.9L, & 4.2L V6 Intake Manifold Gaskets (SS-GA-F-15A)

ISSUE:

On the workhorse 3.8L, 3.9L, and 4.2L Ford V6 engines, intake manifold gasket design and construction may lead to a problem. Brand F shares a common bead for coolant and intake ports and is constructed of silicone rubber. Brand OE utilizes silicone rubber in a separate coolant port bead. In both gasket designs, coolant comes in contact with silicone. In the Brand F gasket design, oil as well as coolant, comes in contact with silicone. The result, in both cases, is swelling of the silicone which can contribute to premature gasket failure.

RESOLUTION:

MAHLE Original has utilized a type of molded rubber beading called fluoroelastomer (FKM) on its replacement gasket for the 3.8L, 3.9L, and 4.2L Ford engine. FKM is both oil and acid resistant – perfect for an environment, like these Ford engines, where oil and coolant contact the manifold gasket sealing beads. FKM is long proven in harsh industrial and automotive environments. We also updated our sealing bead design to parallel OE improvements as shown in the top illustration with the green FKM sealing beads.

APPLICATION:

MAHLE Original part numbers are:

- MS16230 Ford V6, 3.8L, 2000-2004, 3.9L 2004. Ford Truck V6, 3.9L 2004-2007, 4.2L, 2000-2008

- MS16230-1* Ford Truck V6, 256, 3.8L, (Vin 2) 2000-2003, Windstar.

Download PDF [PDF; 773 KB]

3.8L Intake Manifold Isolator Bolts (SS-GA-F-16)

ISSUE:

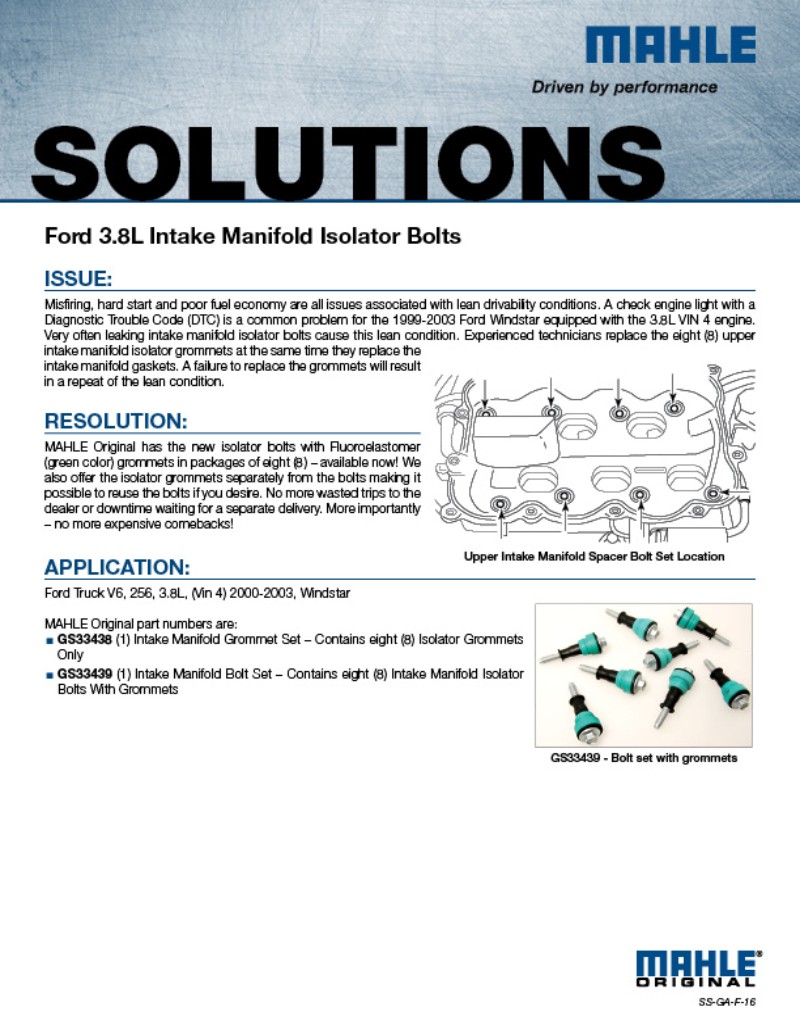

Misfiring, hard start and poor fuel economy are all issues associated with lean drivability conditions. A check engine light with a Diagnostic Trouble Code (DTC) is a common problem for the 1999-2003 Ford Windstar equipped with the 3.8L VIN 4 engine. Very often leaking intake manifold isolator bolts cause this lean condition. Experienced technicians replace the eight (8) upper intake manifold isolator grommets at the same time they replace the intake manifold gaskets. A failure to replace the grommets will result in a repeat of the lean condition.

RESOLUTION:

MAHLE Original has the new isolator bolts with Fluoroelastomer (green color) grommets in packages of eight (8) – available now! We also offer the isolator grommets separately from the bolts making it possible to reuse the bolts if you desire. No more wasted trips to the dealer or downtime waiting for a separate delivery. More importantly – no more expensive comebacks!

APPLICATION:

Ford Truck V6, 256, 3.8L, (Vin 4) 2000-2003, Windstar

Victor Reinz part numbers are:

- GS33438 (1) Intake Manifold Grommet Set – Contains eight (8) Isolator Grommets Only

- GS33439 (1) Intake Manifold Bolt Set – Contains eight (8) Intake Manifold Isolator Bolts With Grommets

Download PDF [PDF; 429 KB]

General Motors

2.3L “Quad Four” Head Gasket (SS-GA-G-01)

ISSUE:

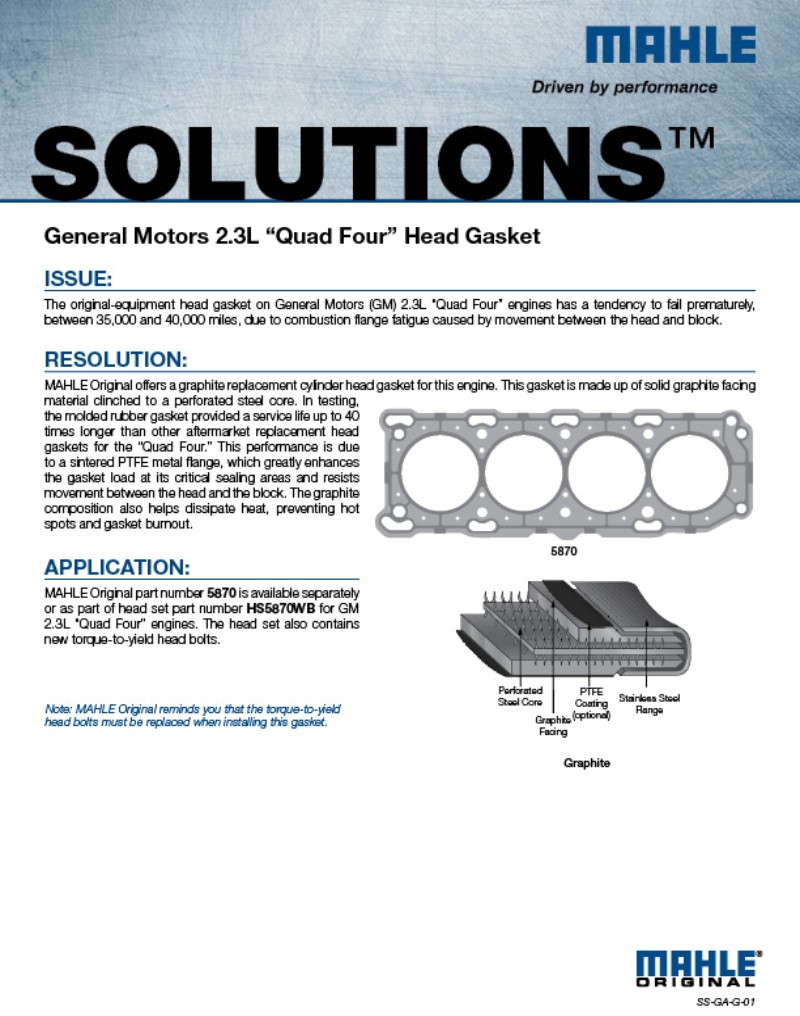

The original-equipment head gasket on General Motors (GM) 2.3L “Quad Four” engines has a tendency to fail prematurely, between 35,000 and 40,000 miles, due to combustion flange fatigue caused by movement between the head and block.

RESOLUTION:

MAHLE Original offers a graphite replacement cylinder head gasket for this engine. This gasket is made up of solid graphite facing material clinched to a perforated steel core. In testing, the graphite gasket provided a service life up to 40 times longer than other aftermarket replacement head gaskets for the “Quad Four.” This performance is due to a sintered PTFE metal flange, which greatly enhances the gasket load at its critical sealing areas and resists movement between the head and the block. The graphite composition also helps dissipate heat, preventing hot spots and gasket burnout.

APPLICATION:

MAHLE Original part number 5870 is available separately or as part of head set part number HS5870WB for GM 2.3L “Quad Four” engines. The head set also contains new torque-to-yield head bolts.

Download PDF [PDF; 363 KB]

4.5L Head Gasket (SS-GA-G-02)

ISSUE:

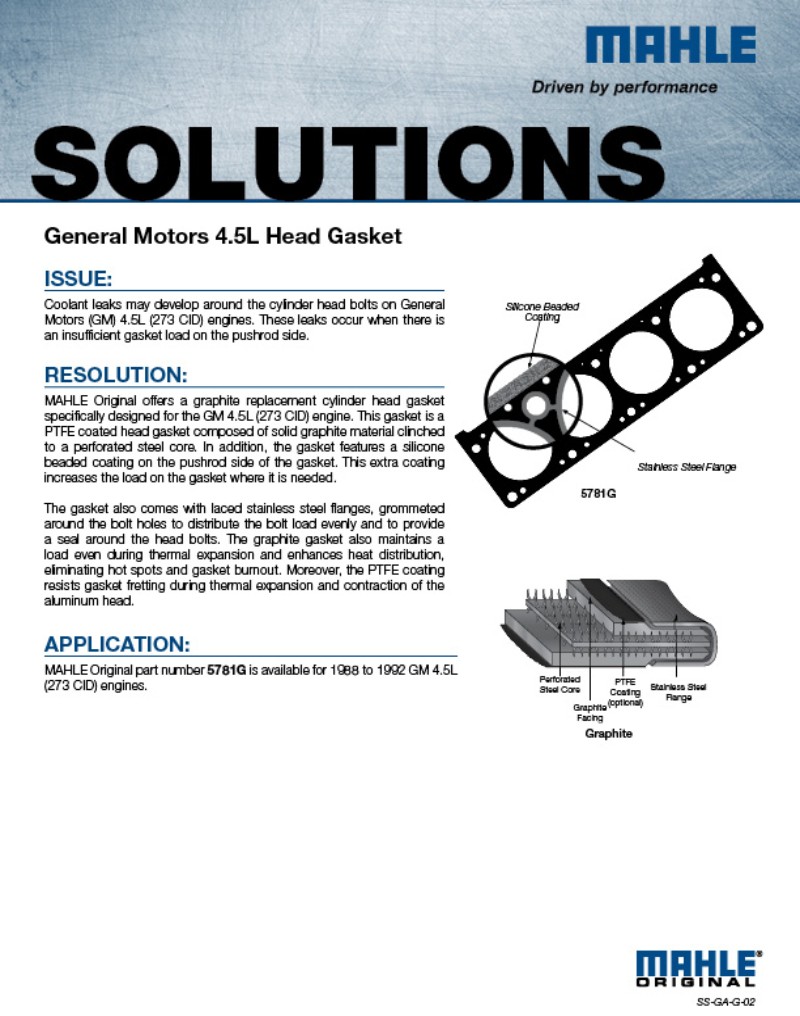

Coolant leaks may develop around the cylinder head bolts on General Motors (GM) 4.5L (273 CID) engines. These leaks occur when there is an insufficient gasket load on the pushrod side.

RESOLUTION:

MAHLE Original offers a graphite replacement cylinder head gasket specifically designed for the GM 4.5L (273 CID) engine. This gasket is a PTFE-coated head gasket composed of solid graphite material clinched to a perforated steel core. In addition, the gasket features a silicone beaded coating on the pushrod side of the gasket. This extra coating increases the load on the gasket where it is needed.

The gasket also comes with laced stainless steel flanges, grommeted around the bolt holes to distribute the bolt load evenly and to provide a seal around the head bolts. The graphite gasket also maintains a load even during thermal expansion and enhances heat distribution, eliminating hot spots and gasket burnout. Moreover, the PTFE coating resists gasket fretting during thermal expansion and contraction of the aluminum head.\

APPLICATION:

MAHLE Original part number 5781G is available for 1988 to 1992 GM 4.5L (273 CID) engines.

Download PDF [PDF; 388 KB]

4.3L Head Gasket (SS-VR-G-03)

ISSUE:

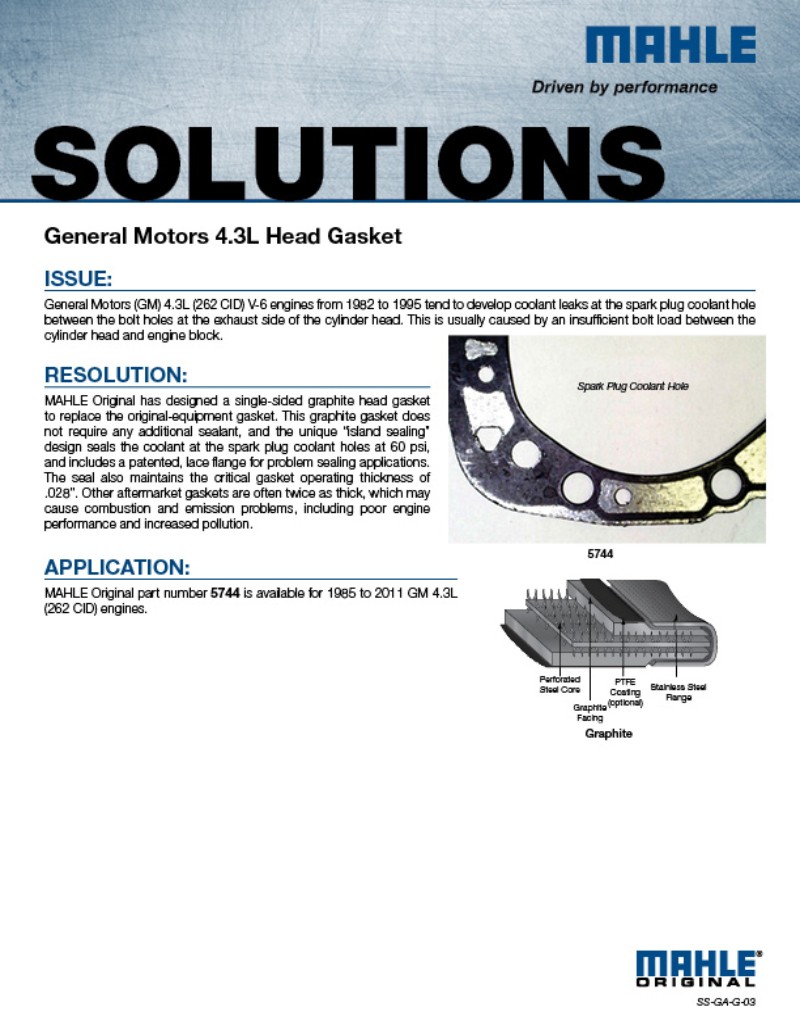

General Motors (GM) 4.3L (262 CID) V-6 engines from 1982 to 1995 tend to develop coolant leaks at the spark plug coolant hole between the bolt holes at the exhaust side of the cylinder head. This is usually caused by an insufficient bolt load between the cylinder head and engine block.

RESOLUTION:

MAHLE Original has designed a single-sided graphite head gasket to replace the original-equipment gasket. This graphite gasket does not require any additional sealant, and the unique “island sealing” design seals the coolant at the spark plug coolant holes at 60 psi, and includes a patented, lace flange for problem sealing applications. The seal also maintains the critical gasket operating thickness of .028”. Other aftermarket gaskets are often twice as thick, which may cause combustion and emission problems, including poor engine performance and increased pollution.

APPLICATION:

MAHLE Original part number 5744 is available for 1985 to 2011 GM 4.3L (262 CID) engines.

Download PDF [PDF; 521 KB]

7.4L Head Gasket (SS-GA-G-05)

ISSUE:

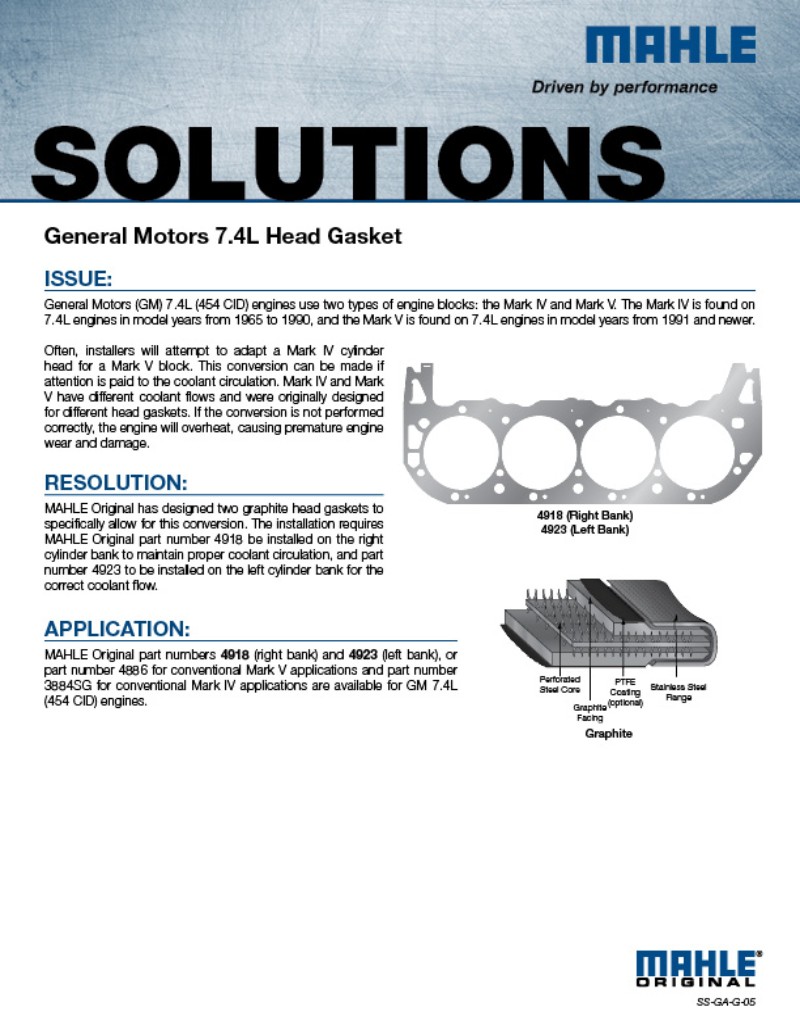

General Motors (GM) 7.4L (454 CID) engines use two types of engine blocks: the Mark IV and Mark V. The Mark IV is found on 7.4L engines in model years from 1965 to 1990, and the Mark V is found on 7.4L engines in model years from 1991 and newer.

Often, installers will attempt to adapt a Mark IV cylinder head for a Mark V block. This conversion can be made if attention is paid to the coolant circulation. Mark IV and Mark V have different coolant flows and were originally designed for different head gaskets. If the conversion is not performed correctly, the engine will overheat, causing premature engine wear and damage.

RESOLUTION:

MAHLE Original has designed two graphite head gaskets to specifically allow for this conversion. The installation requires MAHLE Original part number 4918 be installed on the right cylinder bank to maintain proper coolant circulation, and part number 4923 to be installed on the left cylinder bank for the correct coolant flow.

APPLICATION:

MAHLE Original part numbers 4918 (right bank) and 4923 (left bank), or part number 4886 for conventional Mark V applications and part number 3884SG for conventional Mark IV applications are available for GM 7.4L (454 CID) engines.

Download PDF [PDF; 407 KB]

5.7L Oil Pan Gasket (SS-GA-G-12)

ISSUE:

Many technicians have become used to working with a one-piece rubber oil pan gasket, popular on many late-model engines. Consequently, they’ve asked the aftermarket to provide similar style gaskets for engines like the early model General Motors (GM) 5.7L (350 CID) V-8 engines.

RESOLUTION:

MAHLE Original offers a molded rubber replacement oil pan gasket for GM 5.7L (350 CID) engines. This gasket consists of a revolutionary one-piece design for easy installation. In addition, there are no joints to glue, eliminating potential leak paths. The molded rubber gaskets features include load limiters to prevent over tightening, a higher temperature resistance than cork-rubber gaskets, and no torque loss after installation. MAHLE Original also offers two different part numbers, one for the right side and one for the left side, so there is no need for cutting or fabrication.

APPLICATION:

MAHLE Original part numbers 0S30568RLH (left side) and 0S30568RRH (right side) are available for 1975 to 1985 GM 5.7L (350 CID) V-8 engines. MAHLE Original also offers one-piece oil pan gaskets for many other small block GM engines.

Download PDF [PDF; 339 KB]

4.3L Oil Pan Gasket (SS-GA-G-13)

ISSUE:

Some late-model engines, like the 1986 to 1993 General Motors (GM) 4.3L (262 CID) V-6 engine, are specifically designed to use a molded silicone rubber oil pan gasket.

RESOLUTION:

MAHLE Original offers a molded silicone rubber oil pan gasket for the GM 4.3L engine. This one-piece gasket is designed for easy installation. The molded rubber gasket features compression limiters for a secure seal and to prevent over torquing, as well as increased temperature resistance over cork-rubber gaskets. The gasket does not require a sealant, since there are no joints, and after installation, there is no torque loss, which improves sealing. The superior molded rubber design helps eliminate costly comebacks.

APPLICATION:

MAHLE Original part number OS32485 is available for 1986 to 1993 GM 4.3L (262 CID) engines. MAHLE Original also offers oil pan and valve cover molded rubber gaskets for many other GM, Ford, and import applications.

Download PDF [PDF; 335 KB]

3.4L V-6 Intake Manifold Gasket (SS-GA-G-18)

ISSUE:

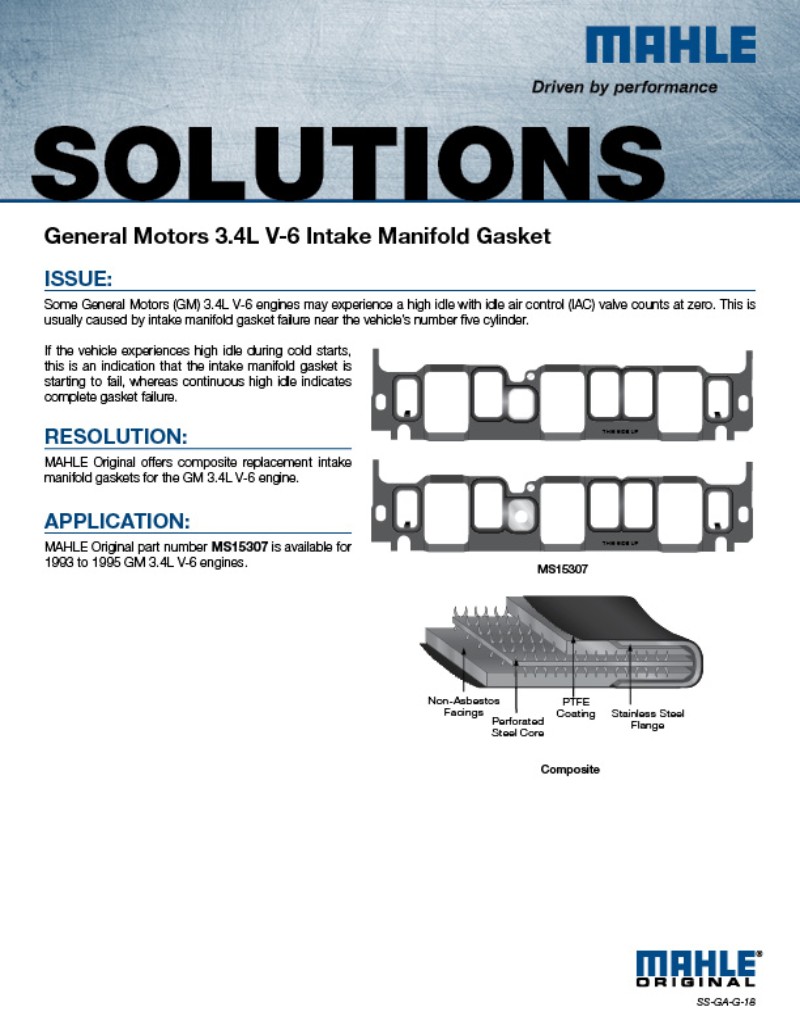

Some General Motors (GM) 3.4L V-6 engines may experience a high idle with idle air control (IAC) valve counts at zero. This is usually caused by intake manifold gasket failure near the vehicle’s number five cylinder.

If the vehicle experiences high idle during cold starts, this is an indication that the intake manifold gasket is starting to fail, whereas continuous high idle indicates complete gasket failure.

RESOLUTION:

MAHLE Original offers composite replacement intake manifold gaskets for the GM 3.4L V-6 engine.

APPLICATION:

MAHLE Original part number MS15307 is available for 1993 to 1995 GM 3.4L V-6 engines.

Download PDF [PDF; 349 KB]

4.3L V-6 and 5.0L, 5.7L V-8 Vortec™ Intake Manifold Installation Sets (SS-GA-G-20A)

ISSUE:

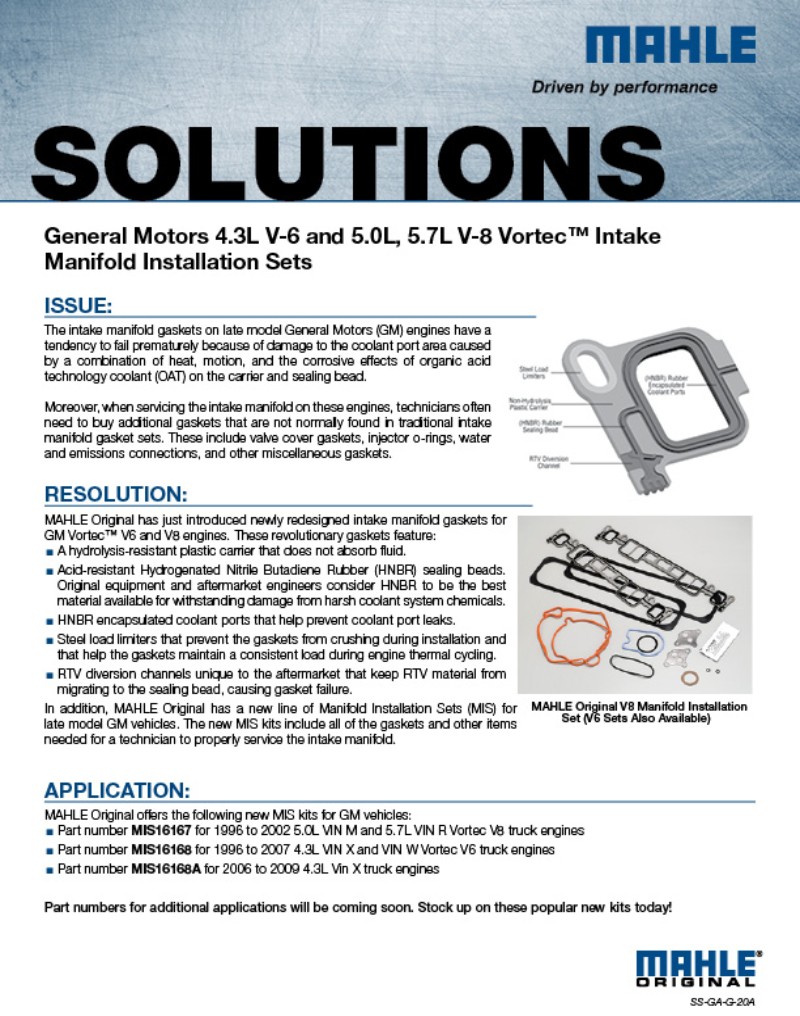

The intake manifold gaskets on late model General Motors (GM) engines have a tendency to fail prematurely because of damage to the coolant port area caused by a combination of heat, motion, and the corrosive effects of organic acid technology coolant (OAT) on the carrier and sealing bead.

Moreover, when servicing the intake manifold on these engines, technicians often need to buy additional gaskets that are not normally found in traditional intake manifold gasket sets. These include valve cover gaskets, injector o-rings, water and emissions connections, and other miscellaneous gaskets.

RESOLUTION:

MAHLE Original has just introduced newly redesigned intake manifold gaskets for GM Vortec™ V6 and V8 engines. These revolutionary gaskets feature:

- A hydrolysis-resistant plastic carrier that does not absorb fluid.

- Acid-resistant Hydrogenated Nitrile Butadiene Rubber (HNBR) sealing beads. Original equipment and aftermarket engineers consider HNBR to be the best material available for withstanding damage from harsh coolant system chemicals.

- HNBR encapsulated coolant ports that help prevent coolant port leaks.

- Steel load limiters that prevent the gaskets from crushing during installation and that help the gaskets maintain a consistent load during engine thermal cycling.

- RTV diversion channels unique to the aftermarket that keep RTV material from migrating to the sealing bead, causing gasket failure.

In addition, MAHLE Original has a new line of Manifold Installation Sets (MIS) for late model GM vehicles. The new MIS kits include all of the gaskets and other items needed for a technician to properly service the intake manifold.

APPLICATION:

MAHLE Original offers the following new MIS kits for GM vehicles:

- Part number MIS16167 for 1996 to 2002 5.0L VIN M and 5.7L VIN R Vortec V8 truck engines

- Part number MIS16168 for 1996 to 2007 4.3L VIN X and VIN W Vortec V6 truck engines

- Part number MIS16168A for 2006 to 2009 4.3L Vin X truck engines

Part numbers for additional applications will be coming soon. Stock up on these popular new kits today!

Download PDF [PDF; 608 KB]

3.1L and 3.4L Intake Manifold Installation Sets (SS-GA-G-22)

ISSUE:

The intake manifold gaskets on late model General Motors (GM) engines have a tendency to fail prematurely because of damage to the coolant port area caused by a combination of heat, motion, and the corrosive effects of organic acid technology coolant (OAT) on the carrier and sealing bead.

Moreover, when servicing the intake manifold on these engines, technicians often need to buy additional gaskets that are not normally found in traditional intake manifold gasket sets. These include valve cover gaskets, injector o-rings, water and emissions connections, and other miscellaneous gaskets.

RESOLUTION:

MAHLE Original redesigned the intake manifold gaskets for GM 3.1L & 3.4L V6 engines. This revolutionary gasket features:

- A hydrolysis-resistant plastic carrier that does not absorb fluid.

- Acid-resistant Hydrogenated Nitrile Butadiene Rubber (HNBR) sealing beads. Original equipment and aftermarket engineers consider HNBR to be the best material available for withstanding damage from harsh coolant system chemicals.

- HNBR encapsulated coolant ports that help prevent coolant port leaks.

- Steel load limiters that prevent the gaskets from crushing during installation and that help the gaskets maintain a consistent load during engine thermal cycling.

- RTV diversion channels unique to the aftermarket that keep RTV material from migrating to the sealing bead, causing gasket failure.

In addition, MAHLE Original has a Manifold Installation Set (MIS) for the GM V6 engine. The MIS kit includes all of the gaskets and other items needed for a technician to properly service the intake manifold.

APPLICATION:

MAHLE Original part numbers are:

- MIS16166 - GM Car 3.1L OHV VIN M V6 1993-1996

- MIS16259* - GM Car 3.1L VIN J, 3.4L VIN E 1999-2005 & GM Truck 3.4L VIN E V6 1996-2005

- MIS17892 - GM Car 3.1L OHV VIN M V6 1995-1999

- MIS16259WB - GM Car 3.1L VIN J, 3.4L VIN E 1999-2005 & GM Truck 3.4L VIN E V6 1996-2005

* Manifold installation bolts (GS33420) sold separately.

Download PDF [PDF; 716 KB]

LS Series Gen III & IV 4.8L, 5.3L & 6.0L Consolidated Multi-Layered Steel Cylinder Head Gaskets (SS-GA-G-24)

ISSUE:

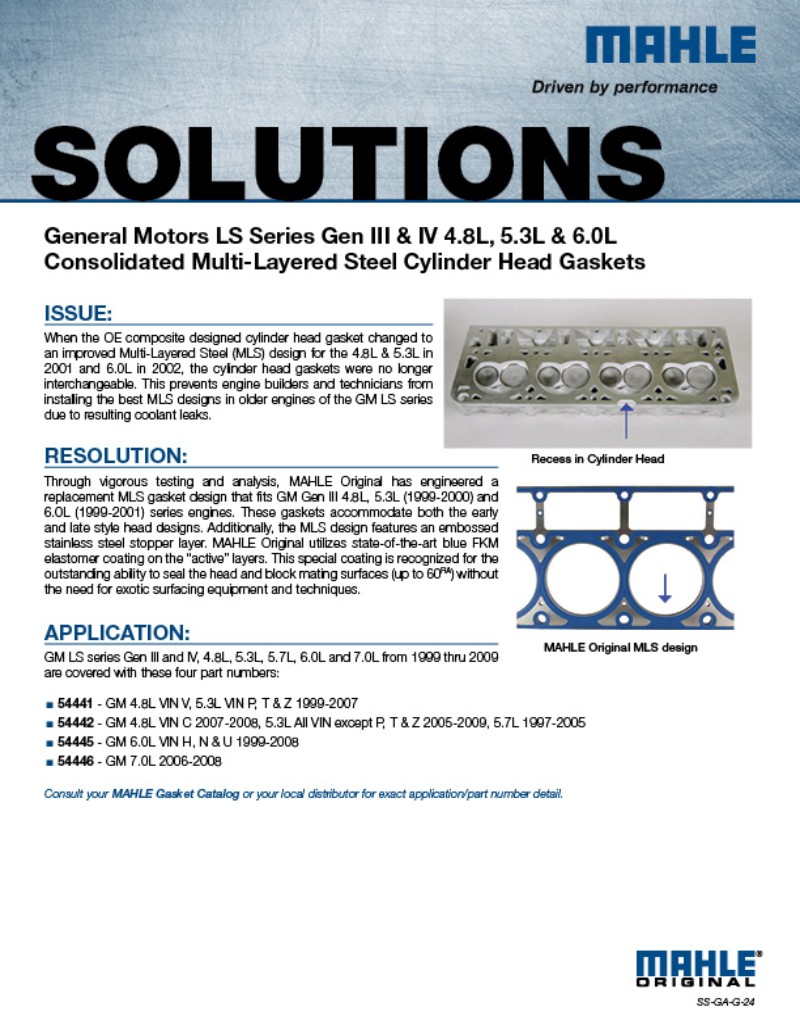

When the OE composite designed cylinder head gasket changed to an improved Multi-Layered Steel (MLS) design for the 4.8L & 5.3L in 2001 and 6.0L in 2002, the cylinder head gaskets were no longer interchangeable. This prevents engine builders and technicians from installing the best MLS designs in older engines of the GM LS series due to resulting coolant leaks.

RESOLUTION:

Through vigorous testing and analysis, MAHLE Original has engineered a replacement MLS gasket design that fits GM Gen III 4.8L, 5.3L (1999-2000) and 6.0L (1999-2001) series engines. These gaskets accommodate both the early and late style head designs. Additionally, the MLS design features an embossed stainless steel stopper layer. MAHLE Original utilizes state-of-the-art blue FKM elastomer coating on the “active” layers. This special coating is recognized for the outstanding ability to seal the head and block mating surfaces (up to 60RA) without the need for exotic surfacing equipment and techniques.

APPLICATION:

GM LS series Gen III and IV, 4.8L, 5.3L, 5.7L, 6.0L and 7.0L from 1999 thru 2009 are covered with these four part numbers:

- 54441 - GM 4.8L VIN V, 5.3L VIN P, T & Z 1999-2007

- 54442 - GM 4.8L VIN C 2007-2008, 5.3L All VIN except P, T & Z 2005-2009, 5.7L 1997-2005

- 54445 - GM 6.0L VIN H, N & U 1999-2008

- 54446 - GM 7.0L 2006-2008

Download PDF [PDF; 550 KB]

Saturn VUE 3.0L Intake Manifold Set (SS-GA-G-26)

ISSUE:

Spark plugs should be changed every 60,000 – 100,000 miles on the 3.0 L Saturn VUE 2002 – 2003 VIN B model. What you may not know is that when they are changed, an OEM aluminum intake plenum has to be purchased from the dealer which can turn into a costly tune-up.

RESOLUTION:

MAHLE Original has designed press-in-place gaskets that allow you to reuse the intake plenum for a fraction of the cost. The MAHLE Original intake manifold gasket set is application engineered to fit precisely into the OEM intake plenum. Smooth flashing lines also ensure ease of installation.

You should be cautious, as with any press in place gasket, to make sure the sealing bead is vertical and not turned over to assist in preventing leaks. Visit youtube.com/mahleclevite for a video on how to properly install this gasket set.

APPLICATION:

MAHLE Original part number MS19490 is available fitting 2002 – 2003 Saturn VUE 3.0L VIN B engines.

Download PDF [PDF; 647 KB]

Other

3.4L Toyota Truck Head Gasket (SS-GA-I-02A)

Issue:

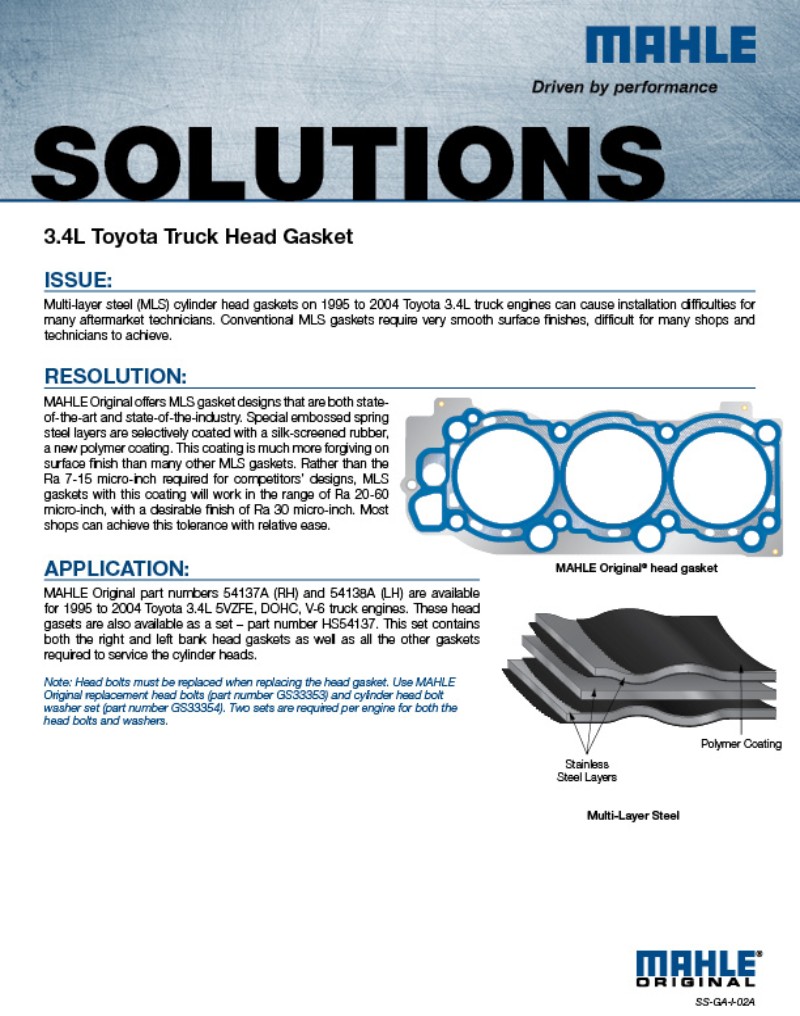

Multi-layer steel (MLS) cylinder head gaskets on 1995 to 2004 Toyota 3.4L truck engines can cause installation difficulties for many aftermarket technicians. Conventional MLS gaskets require very smooth surface finishes, difficult for many shops and technicians to achieve.

Resolution:

MAHLE Original offers MLS gasket designs that are both stateof-the-art and state-of-the-industry. Special embossed spring steel layers are selectively coated with silk-screened rubber, a new polymer coating. This coating is much more forgiving on surface finish than many other MLS gaskets. Rather than the Ra 7-15 micro-inch required for competitors’ designs, MLS gaskets with this coating will work in the range of Ra 20-60 micro-inch, with a desirable finish of Ra 30 micro-inch. Most shops can achieve this tolerance with relative ease.

Application:

MAHLE Original part numbers 54137A (RH) and 54138A (LH) are available for 1995 to 2004 Toyota 3.4L 5VZFE, DOHC, V-6 truck engines. These head gaskets are also available as a set – part number HS54137. This set contains both the right and left bank head gaskets as well as all the other gaskets required to service the cylinder heads.

Download PDF [PDF; 355 KB]

Cummins N-14 “Rocker Box to Head” Gasket (SS-GA-HD-04)

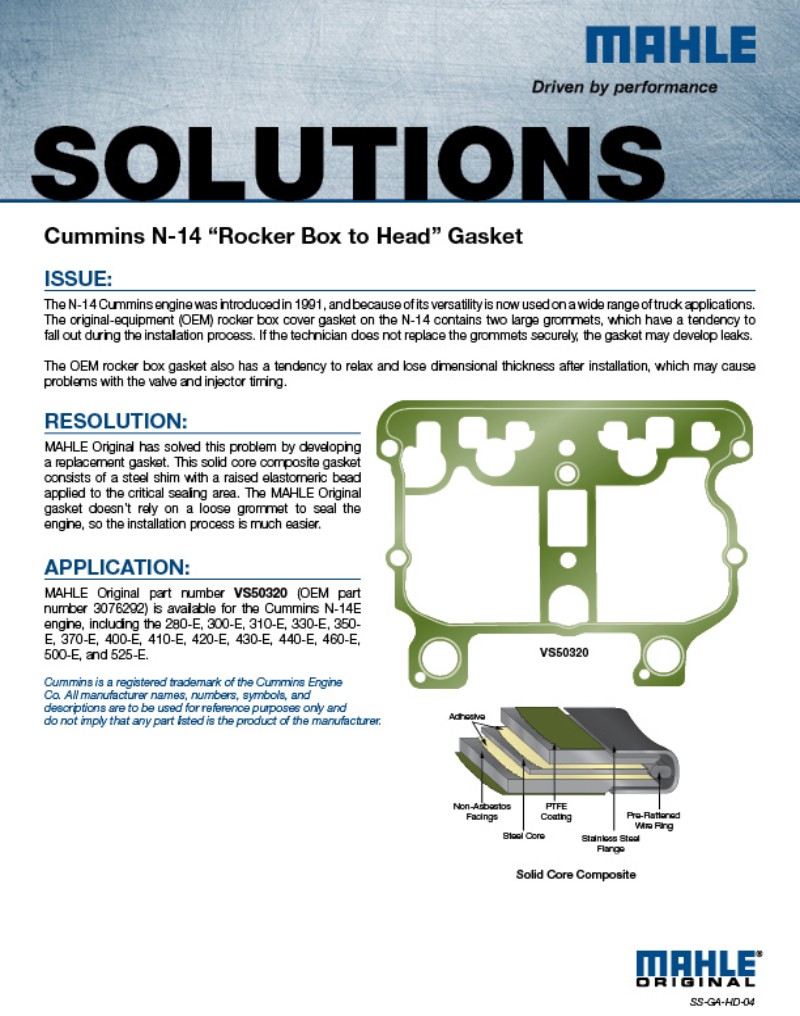

ISSUE:

The N-14 Cummins engine was introduced in 1991, and because of its versatility is now used on a wide range of truck applications. The original-equipment (OEM) rocker box cover gasket on the N-14 contains two large grommets, which have a tendency to fall out during the installation process. If the technician does not replace the grommets securely, the gasket may develop leaks.

The OEM rocker box gasket also has a tendency to relax and lose dimensional thickness after installation, which may cause problems with the valve and injector timing.

RESOLUTION:

MAHLE Original has solved this problem by developing a replacement gasket. The solid core composite gasket consists of a steel shim with a raised elastomeric bead applied to the critical sealing area. The MAHLE Original gasket doesn’t rely on a loose grommet to seal the engine, so the installation process is much easier.

APPLICATION:

MAHLE Original part number VS50320 (OEM part number 3076292) is available for the Cummins N-14E engine, including the 280-E, 300-E, 310-E, 330-E, 350-E, 370-E, 400-E, 410-E, 420-E, 430-E, 440-E, 460-E, 500-E, and 525-E.

Download PDF [PDF; 344 KB]

Head Bolts and Fasteners (SS-GA-M-04)

ISSUE:

Head bolts are elastic. Tightened and under load in the engine they are stretched. When the load is released or when the bolt is backed off, the head bolt returns to its approximate original length. All bolts or threaded fasteners have a yield point. When the yield point is reached during the tightening process, the bolt loses some of its elasticity and does not return to its original length when the load is released. It’s quite common for engine manufacturers to tighten bolts to the yield point. Torque-to-yield fasteners are found on domestic and import light-duty and heavy-duty engines. Because the bolts may lose their strength and are pushed to their yield point after thousands of engine operating cycles, original-equipment manufacturers (OEMs) recommend the bolts be replaced any time they are removed.

RESOLUTION:

MAHLE Original offers replacement bolts and fasteners for both light-duty and heavy-duty engines. Bolts are supplied in sets and each set is enough for one cylinder head. Our bolts and fasteners meet or exceed the OEM specifications. Tightening instructions are included in each package.

APPLICATION:

MAHLE Original head bolts and fasteners are available in more than 80 part numbers.

Download PDF [PDF; 308 KB]

Exhaust Manifold Gaskets (SS-GA-M-08)

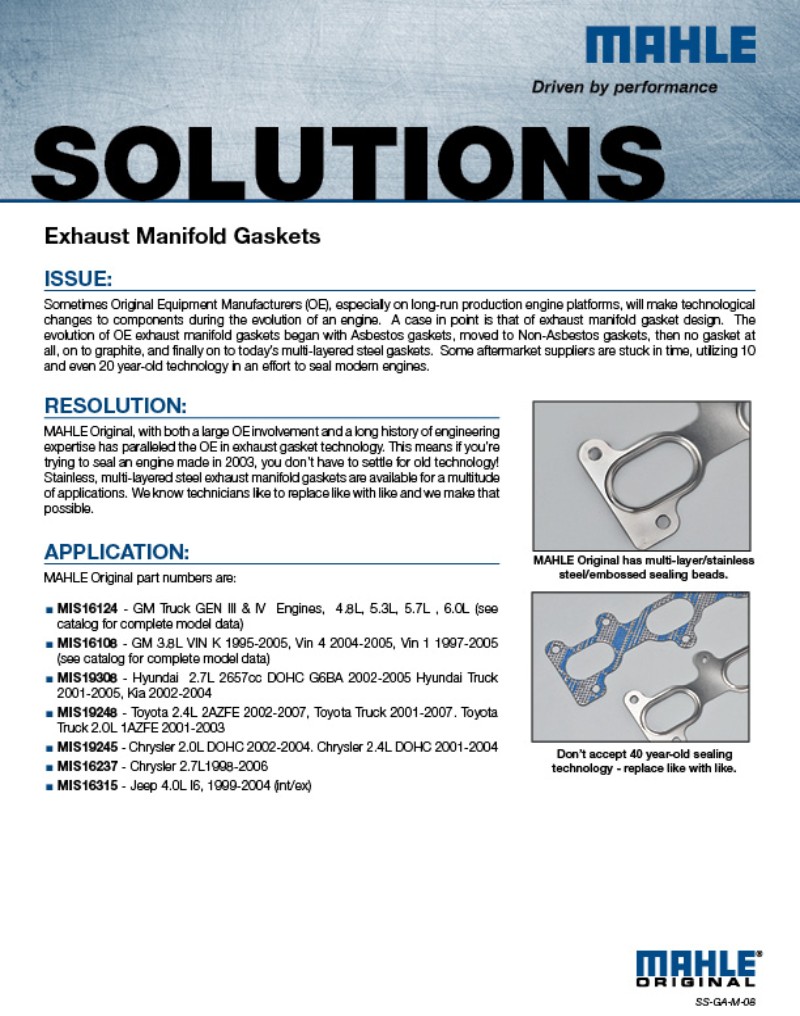

ISSUE:

Sometimes Original Equipment Manufacturers (OE), especially on long-run production engine platforms, will make technological changes to components during the evolution of an engine. A case in point is that of exhaust manifold gasket design. The evolution of OE exhaust manifold gaskets began with Asbestos gaskets, moved to Non-Asbestos gaskets, then no gasket at all, on to Graphite, and finally on to today’s Multi-Layered Steel gaskets. Some aftermarket suppliers are stuck in time, utilizing 10 and even 20 year-old technology in an effort to seal modern engines.

RESOLUTION:

MAHLE Original, with both a large OE involvement and a long history of engineering expertise has paralleled the OE in exhaust gasket technology. This means if you’re trying to seal an engine made in 2003, you don’t have to settle for old technology! Stainless, multi-layered steel exhaust manifold gaskets are available for a multitude of applications. We know technicians like to replace like with like and we make that possible.

APPLICATION:

MAHLE Original part numbers are:

- MIS16124 - GM Truck GEN III & IV Engines, 4.8L, 5.3L, 5.7L , 6.0L (see catalog for complete model data)

- MIS16108 - GM 3.8L VIN K 1995-2005, Vin 4 2004-2005, Vin 1 1997-2005 (see catalog for complete model data)

- MIS19308 - Hyundai 2.7L 2657cc DOHC G6BA 2002-2005 Hyundai Truck 2001-2005, Kia 2002-2004

- MIS19248 - Toyota 2.4L 2AZFE 2002-2007, Toyota Truck 2001-2007. Toyota Truck 2.0L 1AZFE 2001-2003

- MIS19245 - Chrysler 2.0L DOHC 2002-2004. Chrysler 2.4L DOHC 2001-2004

- MIS16237 - Chrysler 2.7L1998-2006

- MIS16315 - Jeep 4.0L I6, 1999-2004 (int/ex)

Download PDF [PDF; 546 KB]