Technicians are increasing their demand for the ability to replace the OE part with a part that looks, feels, and performs as good or better than the original. This is known as OE Form, Fit, and Function ... And MAHLE® gaskets lead the way. 99% of gaskets sold in a MAHLE box meet this standard - far more than any competitor.

Following the MAHLE acquisition of Dana’s engine parts division in 2007 and the creation of MAHLE Aftermarket Inc., MAHLE invested major resources that had been lacking for years in an effort to grow coverage. The MAHLE investment in gasket tooling enabled the expansion to the industry coverage leader it is today. With 10,000 part numbers covering nearly 900,000 applications, no other gasket supplier is even close.

The MAHLE Aftermarket commitment to making Technicians’ lives easier is prevalent in the most thorough bills of materials in the industry. Every component a technician needs to complete a repair, from the biggest head gasket to the smallest o-ring, it can be found in a MAHLE® gasket set. This eliminates costly delays and returns while raising customer satisfaction leading to more money.

The MAHLE Aftermarket gasket team pioneered innovative packaging years ago, and it carries on throughout the MAHLE® gasket line. MAHLE is the only gasket supplier that designed a package enabling a counterperson or technician to either see the actual gaskets inside, or if it is a bigger set packed in a box, every one carries the image of the contents instead of simply a bill of materials like other brands.

With the best coverage on the planet, the MAHLE gasket product offering covers over one million applications worldwide and approximately 200 million vehicle registrations for engines 1990 and newer. This exceptional selection is backed by a full range of technical information, support and training. What comes in the package and what stands behind it is real value that technicians appreciate.

MAHLE Aftermarket has one of the most complete gasket product lines available anywhere. Total coverage for medium and heavy duty truck, commercial marine and industrial applications results in a truly world class source for gaskets. From the simplest composition shapes to advanced multi-layer steel designs, engine gaskets have to be tough. Drastic temperature extremes, high internal pressures, coolants and lubricants of every description... gaskets must handle them all. MAHLE gaskets meet these demanding conditions with unsurpassed standards of innovation and quality.

MAHLE Aftermarket offers MAHLE gasket sets for in-frame, consolidated full sets and many more. When you want gaskets that address the needs of the heavy duty market, look no further than MAHLE heavy duty gaskets.

While other companies attempt to get by with a brand built on older technology - the company built on quality, technology and innovation defines the new gold standard in performance gaskets.

The MAHLE Performance gasket line is built from the ground up, using the latest technology and most advanced materials to seal and protect engines designed to run harder, faster and push beyond the limits of conventional gaskets.

Gasket Materials

Regardless of what application you are trying to seal, you can count on MAHLE Aftermarket doing the research and testing to provide the optimum material and technology for that specific application - this systems sealing approach requires a variety of materials. No other gasket distributor offers the Application Engineered approach to sealing an engine. A variety of different gasket materials insure an engine gets the optimal seal. All gaskets are not created equal - MAHLE® gaskets prove it every day.

Head and intake manifold gasket materials

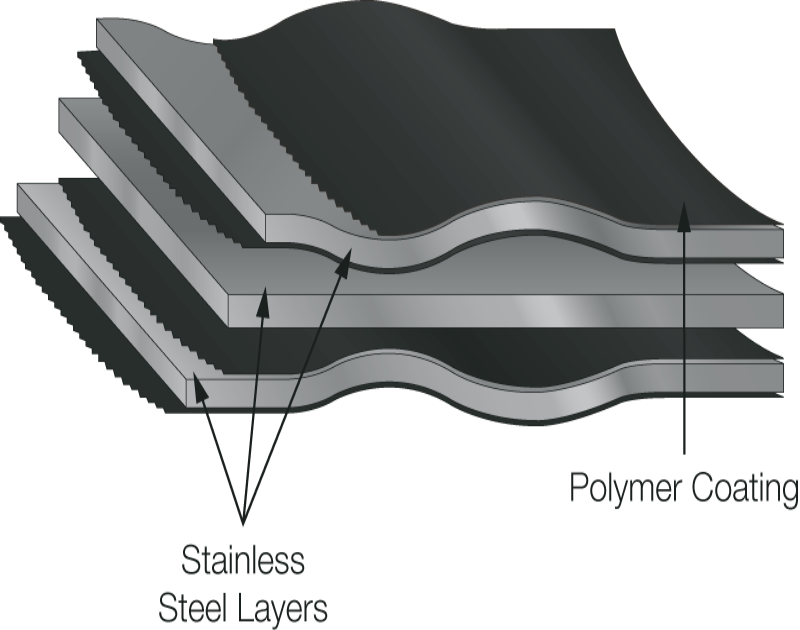

Multi-Layered Steel (MLS) Head & Manifold Gaskets

- Maintains all OE tolerances and requirements

- Polymer coated for positive fluid seal

- Ultimate temperature resistance

- Lower clamping force means less bore distortion

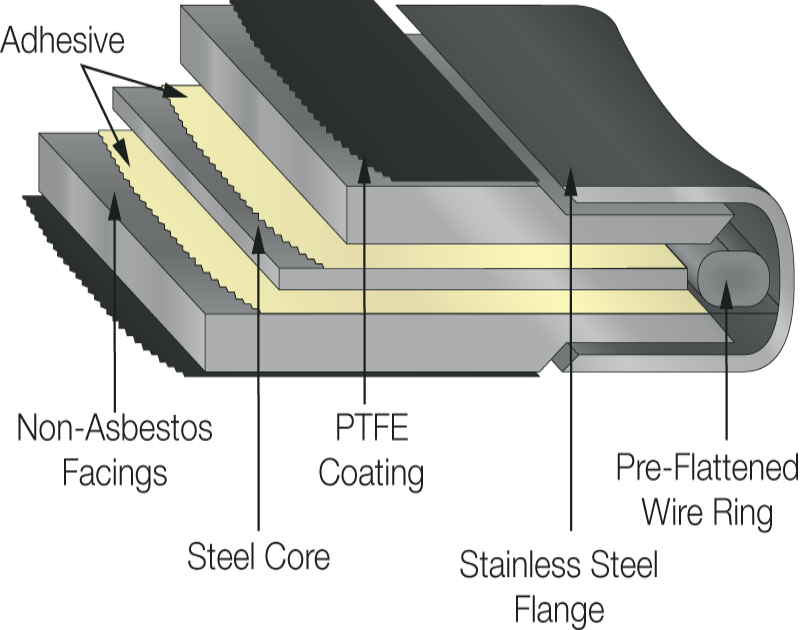

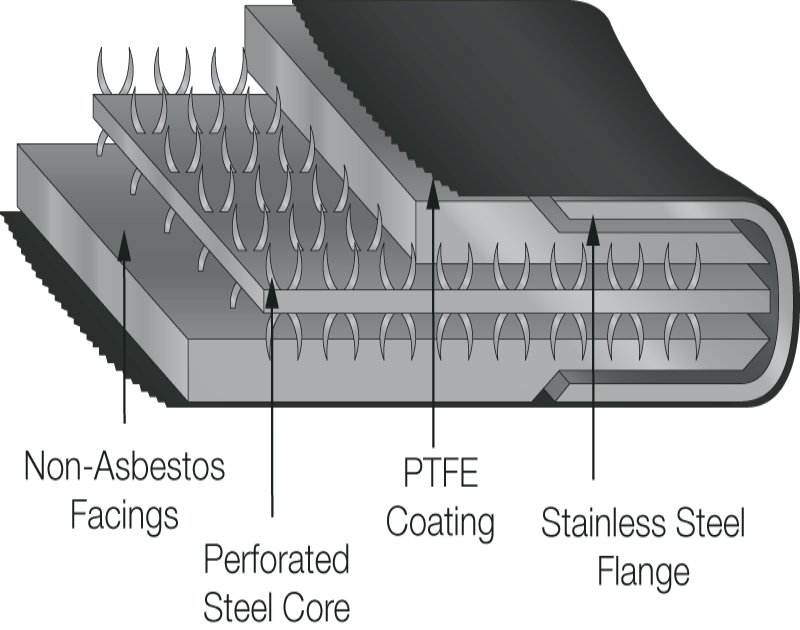

Solid Core Composite Head & Exhaust Manifold Gaskets

- Maintains all OE tolerances and requirements

- Polymer coated for positive fluid seal

- Ultimate temperature resistance

- Lower clamping force means less bore distortion

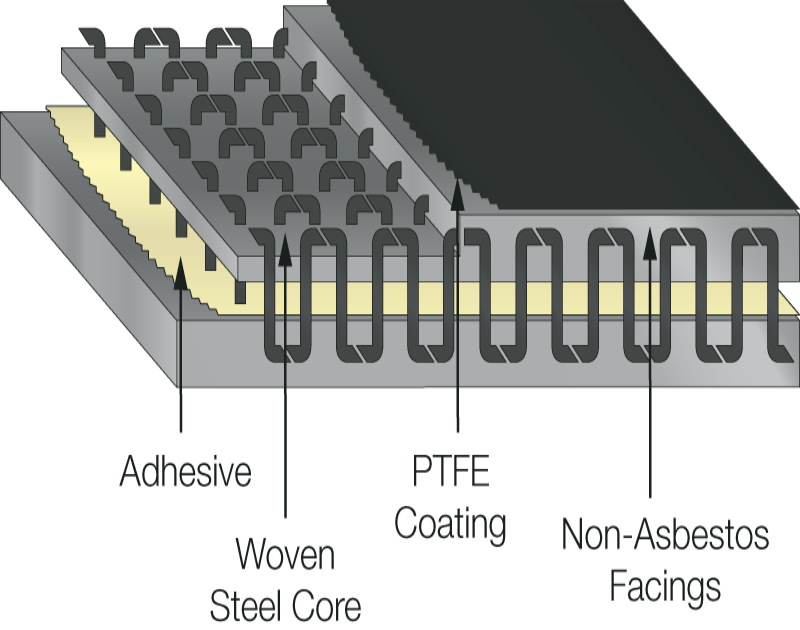

Composite Head & Intake Manifold Gaskets

- Maintains all OE tolerances and requirements

- Polymer coated for positive fluid seal

- Ultimate temperature resistance

- Lower clamping force means less bore distortion

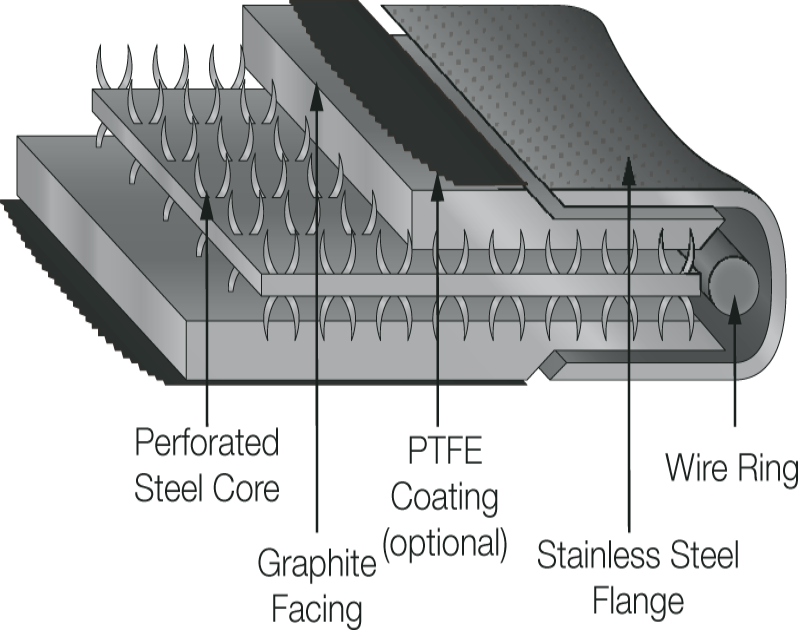

Graphite Head & Manifold Gaskets

- Stays cool at temperature up to 1800° F

- Designed to seal minor surface irregularities

- No re-torque required

- PTFE coating optional

Valve/timing cover, oil pan and other gasket materials

Performance Composite Timing Cover, Water Pump and Differential Gaskets

- Stays cool at temperature up to 1800° F

- Designed to seal minor surface irregularities

- No re-torque required

- PTFE coating optional

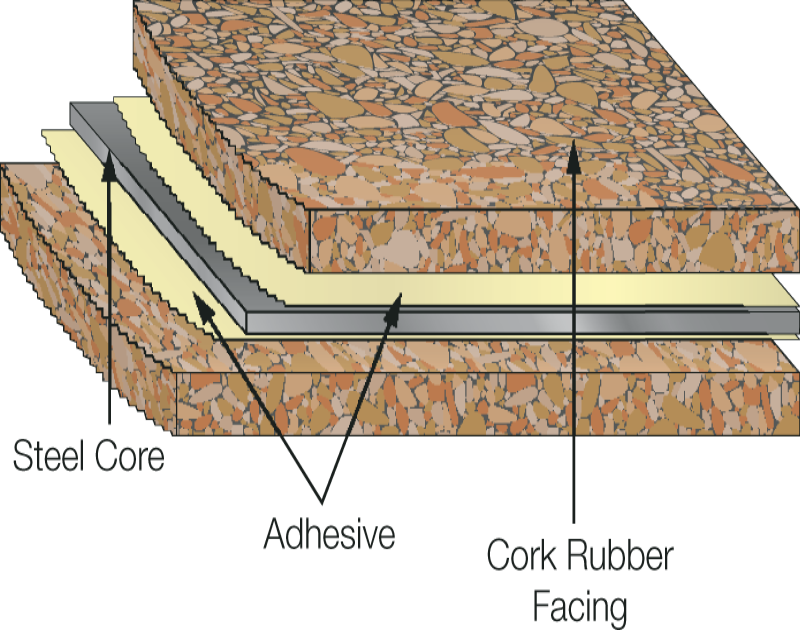

Cork Oil Pan, Timing Cover and Differential Gaskets with Metal Carrier

- Stays cool at temperature up to 1800° F

- Designed to seal minor surface irregularities

- No re-torque required

- PTFE coating optional

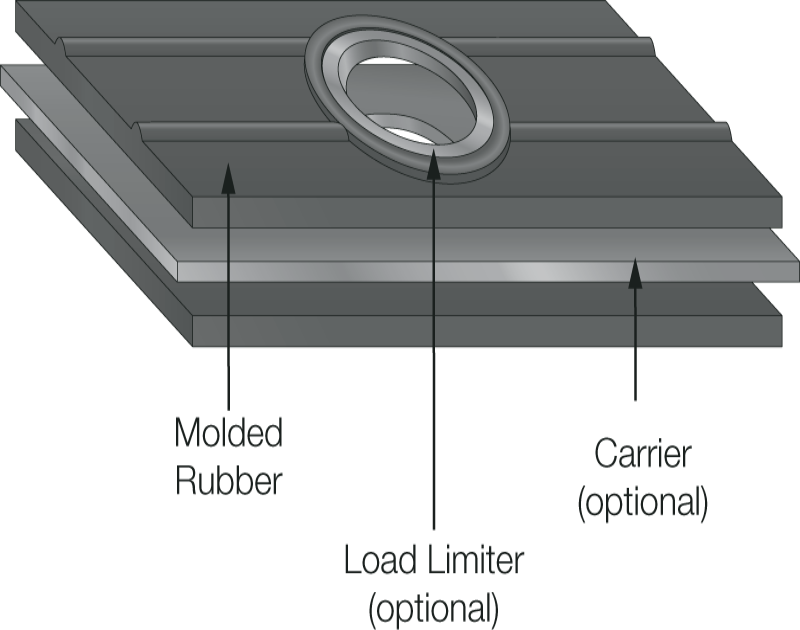

Molded Rubber Valve Cover and Oil Pan Gaskets

- No joints means increased durability

- Sealants not required (except at t-joints)

- Compression limiters prevent over-tightening

- No torque loss or shrinkage