Cabin air filters are very efficient: During only one hour of driving, an air volume of up to 100,000 liters is circulated through the vehicle interior. All the more reason to change cabin air filter elements regularly. MAHLE recommends changing the cabin air filter every 15,000 km or a minimum of at least once per year. If the cabin air filter fails or is clogged, the pollutant concentration in the interior of the vehicle can increase to six times of that of the outside air. MAHLE cabin air filters reliably supply the driver and passengers with clean air to breathe, which safeguards their health, well-being and ability of the driver to concentrate even in the event of smog or high pollen count. They also reduce the load on the blower, protect heating and air conditioning from contamination, improve air circulation and prevent dangerous fogging of the windows. In addition, the inside of the windows and fittings remain cleaner for longer.

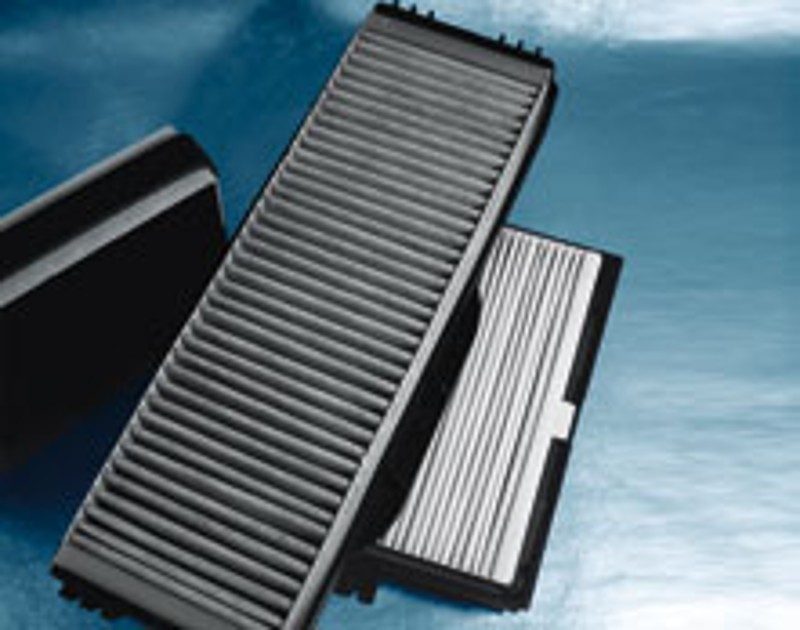

The pleat geometry of our cabin air filter elements is designed to provide a long service life. The low flow resistance minimizes the load on the blowers. Thanks to the accurate fit of the filter elements in the housings, bypass air is prevented.

Our cabin air filters produce no harmful emissions, as solvent-free methods, such as ultrasound welding technology, are used for their production.

Cabin air filters with activated carbon

Cabin air filters with activated carbon elements remove harmful exhaust fumes, dirt and dust as well as high ozone concentrations and unpleasant smells. Their pleat bellows consist of three layers: an activated carbon layer is sandwiched between two layers of non-woven materials. A heat process is used to fuse the filter layers and therefore no solvent containing glues are required. Depending on the vehicle type, activated carbon filters are also available that can be used instead of conventional cabin air filters.

Cost-effective retrofitting for certain older vehicle models

Vehicles that were not originally equipped with cabin air filters can be retrofitted with our cabin air filters, including those with activated carbon. For that purpose, a filter element from our comprehensive program is matched to a housing that is suitable for the particular vehicle.

A bit rough

A CABIN AIR FILTER HAS A LOT OF WORK. AND IT SOMETIMES NEEDS A LITTLE HELP: FROM A COARSE OR PRE-FILTER.

Car manufacturers have been using cabin air filters for many years now to make sure that the passengers get enough clean air to breathe. Whether passenger cars, trucks, buses or agricultural and construction machinery: almost every vehicle today has a “cleaner”—either as a simple particulate filter or combination filter with activated carbon layer. Particulate filters filter solids out of the air we breathe and protect us against fine particulate, pollen, industrial dusts and other microscopic, respirable particles. Activated carbon filters also absorb smells and toxic gases such as nitrogen oxides, petrol vapours or fertilizers and break down up to 99 % of ozone.

Additional coarse filters are often used in vehicles with a long service life that are operated in heavily polluted areas. This type of filter mat can often be seen in traffic as roof-top structures on buses. Others are fitted in the air intake system before the actual cabin air filter and installed as pre-filters in the heater and air-conditioning casing. These coarse filters are used to ensure the maximum filter service life for the complete filter surface area of the cabin air filter: if a mass of coarse particles hits the fanfold surface of the filter this can lead to a premature clogging of the inlet side of the air filter—even to the dreaded pleat bellows clogging that prevents the passage of any air at all. Upstream coarse filters can reduce one-sided clogging of the surface of the cabin air filter on the inlet side, thus helping to ensure that the entire filter capacity is used before the cabin air filter is changed during routine inspections.

CABIN AIR PRE-FILTER (LAP): FOAM OR FLEECE

Pre-filters are normally made of polyester foams or fleece mats. The choice of material depends on the specifications of the vehicle manufacturer.

FOAMED: A HOMOGENEOUS STRUCTURE

Polyester foams consist of a homogeneous block with uniform pores produced by a special thermophysical process, reticulation. After cooling the foam is cut into slices and shaped by cutting dies.

Reticulation – what’s that?

Reticulation is the term used to describe the subsequent removal of foam membranes in a pressure vessel charged with gas. This process produces a uniform, open pore lattice structure with a minimum flow resistance for gases and fluids.

The filter effect of the reticulated material depends on the pore size PPI (pores per inch, in other words the number of open linear pores per inch = 25.4 mm). The higher the PPI number the smaller the particles that can be filtered. Common foams have between PPI 10 and PPI 80. MAHLE Original and Knecht LAP pre-filters are made using foams with a PPI of 30 since extensive laboratory tests have proven the optimum relationship between service life and coarse particle filtration for this pore size.

Polyester foam is resistant to ozone and partly resistant to hydrolysis, it withstands ageing and temperatures up to 90 °C and it is free from plasticizers and CFCs. The material can be recycled and poses no problems for thermal disposal.

Fleece mats: progressive layers

These fleece mats are based on approx. 10 and 20 mm thick polyester fibre mats that are made up of various, progressive layers so that they become denser and denser on the clean air side. This structure combines a maximum filter performance with optimum dust retention properties.

Filter mats are classified in filter classes according to DIN EN 779.

Filter class / filtration efficiency:

- G2 / up to 80%

- G3 / up to 90%

- G4 / > 90%

Weights of between 100 g/m² and 200 g/m² are used depending on the requirements. For example, a G2 filter mat with a weight of 100 g/m² will primarily stop coarse particles whereas a G3 filter mat of the same thickness and a weight of 200 g/m² can filter out much finer particles.

Polyester fleece is hardly flammable (classification of inflammability F1), resistant to hydrolysis, withstands ageing and temperatures up to 100 °C. The material is free from silicon, plasticizers and CFCs, can be recycled and is suitable for thermal disposal.

Catching the dirt

A TIDY JOB

During only one hour driving, an air volume of up to 100,000 litres is blown into the vehicle interior. All the more important is the regular replacement of the cabin air filters. The MAHLE filter experts recommend: replace filters after every 15,000 km or at least once per year. If the cabin air filter is clogged up or fails completely, the pollutant concentration in the interior of the vehicle can increase up to six times of that of the outside air. MAHLE cabin air filters supply driver and passengers reliably with cleaned air to breathe and safeguard their health, well-being and the driver’s ability to concentrate even in the presence of smog or high pollen count.

HOLDING BACK THE DIRT

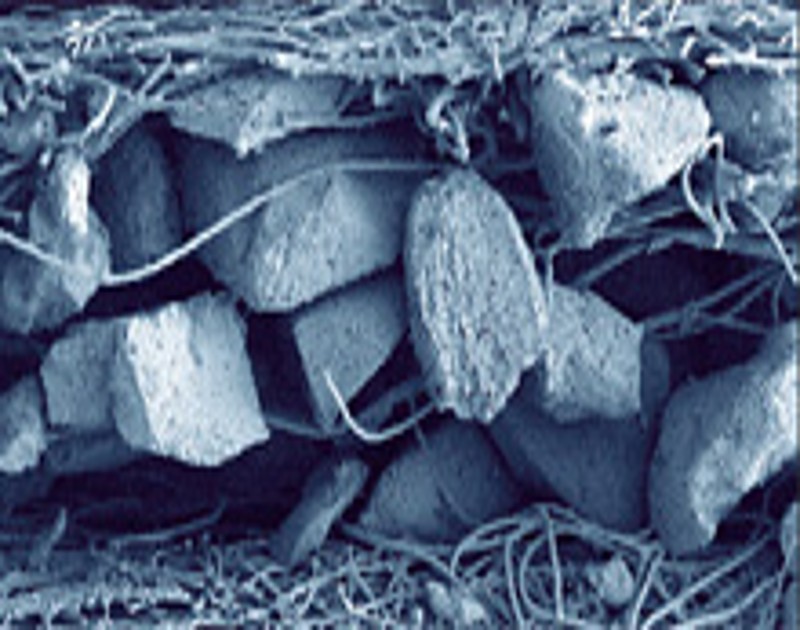

Dirt particles such as dust, pollen or soot, harmful exhaust fumes, high ozone concentrations, unpleasant odours and even fine particulate dust: all these are retained by the cabin air filter – provided it is a combi-filter (LAK) that consists of two fleece layers and an active carbon layer, like this one. Due to the sandwich construction of the combi-filter (see also the scanning electron microscope image), two independent functions have been combined in one filter. The gases (mainly hydrocarbons as well as inorganic and harmful gases such as hydrogen sulphide, sulphur dioxide and nitrogen oxides) are here absorbed by the active carbon layer.

BAD SMELLS FROM OLD FILTERS

A saturated filter reduces the blower output and therefore delays significantly clearing of steamed up windows. If the filter change is postponed for too long, moisture binds to the accumulated dust: the filter becomes a breeding ground for bacteria and mould, which settle in the ducts of the ventilation and air conditioning system and lead to extremely unpleasant odours and harmful emissions into the vehicle interior. We like to give you therefore some tips for fast and safe filter change.

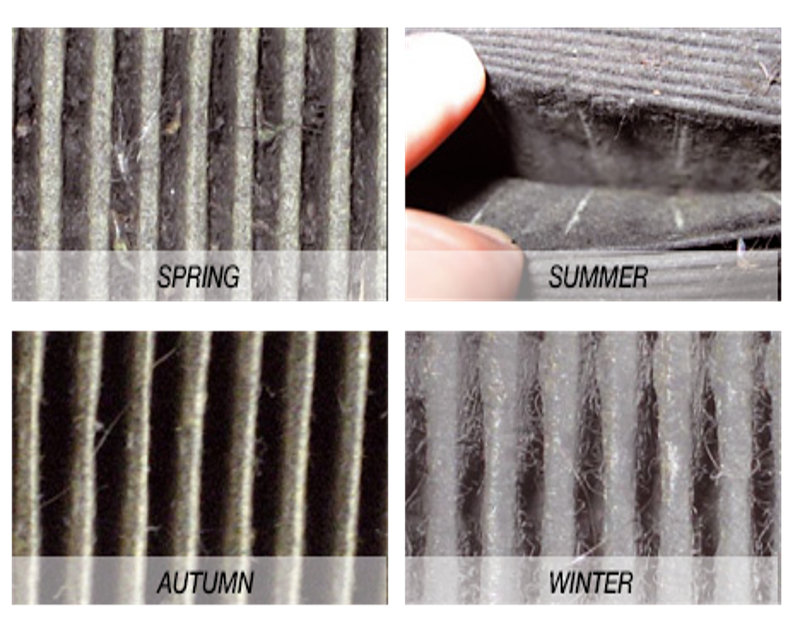

Clean air is always in season

In spring, one can recognize pollen, grass seed and relatively coarse dirt particles. These can even lead to clogging on the surface of the pleat bellows – while the pleats further down remain comparatively clean.

In summer, significantly more soot and fine dust can be found in the filter.

In autumn, the situation is similar to that of summer – however, due to the high air humidity, even more dust and other particles are collected more quickly.

Winter: the year reaches its end and so does the air filter. The filter is so dirty that it can no longer fulfil its intended purpose and will have to be replaced.

A supply of clean air

The commercial vehicle market is booming. This will also enhance the sales prospects for cabin air filters in lorries, transporters and building vehicles. Air conditioning systems with suitable filters have become all but standard equipment in the meantime. However, when a vehicle is used with a clogged cabin air filter, severe consequences for heating and air conditioning systems may be the result. The replacement intervals stipulated by the vehicle manufacturers must therefore be strictly observed. Generally this means: about every 12,000 to 15,000 km. For a lorry that travels an annual distance of 250,000, this would be at least every 3 weeks.

While some years ago only passenger cars were equipped with cabin air filters, there is practically no commercial vehicle today that is not fitted with a filter that protects drivers from polluted air entering the cabin. And that is a good development. Without cabin air filters, drivers in their cabins would be subjected to pollutant concentrations 6 times higher than at the roadside. This is mainly due to the so-called tunnel effect, which means that the exhaust fumes of the vehicles in front are directly drawn into the vehicle interior. But also irritant gases such as ozone, toxic gases such as fertilizers and diesel exhaust particulate and other irritants such as pollen and annoying smells would get straight into the interior without cabin air filters. MAHLE Filter and Knecht cabin air filters are both available as particulate and combination filters. Particulate filters protect from fine dust, but also from pollen, industrial fallout and other very fine particulates that can reach the lungs. In addition, active carbon filters absorb smells and gases and reduce up to 99 % of ozone.

THE STRUCTURE OF A CABIN AIR FILTER WITH ACTIVE CARBON

A layer of special active carbon granules is sandwiched between two fleece layers. The unpleasant smells are deposited in the pores of the active carbon. Active carbon consists mainly of carbon (mostly > 90 %) with an extremely porous structure. The pores are interconnected like in a sponge. Just 2 grams of active carbon are roughly equivalent to the surface area of a football pitch – a standard filter containing about 200 g carbon has therefore a filter surface of about 100 football pitches.

CABIN AIR FILTERS FOR COMMERCIAL VEHICLES: THE FINE AND THE COARSE

In contrast to passenger vehicles, commercial vehicles are often used in dusty environments such as building sites. Their cabin air filters must therefore not only eliminate smallest particulate from the cabin, but also coarse particulate. However, the finer the filtration, the more dirt is removed – and the faster the dirt absorption capacity is exhausted. It is the task of the R&D engineers to combine the required fine filtration with a long service life. When the coarse particulate load is extremely high as, for instance, at a building site or a quarry, the filter must be replaced more often.

Service intervals: only a guideline

Cabin air filters are mostly located in front of the vehicle's heating or air conditioning system, where the polluted outside air is drawn in and blown into the vehicle interior after cleaning – this can be up to 150 l air per second when the filter is in optimum condition. For clogged filters, this air volume is reduced. This can be noted clearly, when only a limited amount of air reaches the passenger compartment, although the blower is set to maximum (if in doubt, a visual check of the filter will help). When the filter is clogged, it is high time for replacement regardless of the distance covered since the last filter change. If this is not done, expensive consequential damage of heating or air conditioning can result.