Modern fuel injection systems require an extremely clean, homogeneous and free-flowing fuel supply. However, contaminants can get into the fuel during the production and transport process and need to be filtered out. MAHLE fuel filters reliably remove contaminants. Thanks to high-quality filter media, the fuel system is protected from the smallest contaminants and therefore from corrosion damage. This protects the engine and assures efficient operation of the vehicle. The required constant fuel supply is achieved with pressure regulation and recirculation of the surplus fuel from the injection pump to the tank.

Pulsation damping compensates for the pressure fluctuations caused by the fuel pump. Our fuel filters comply with the correspondingly high safety standards of the automobile manufacturers and ensure secure sealing even in the event of accidents.

However, an important consideration for optimum functioning of fuel filters is that filters are replaced within the maintenance intervals stipulated by the automobile manufacturers.

Function of MAHLE diesel fuel filters

In order to prevent paraffin separation and clogging of the filter at low ambient temperatures, pre-warming with electric heating elements or recirculation of fuel that has been warmed by the engine is used in our fuel filters.

For newer generations with even higher requirements, MAHLE has opted for two separate filter stages during water separation.

The first filter phase consists of a cellulose filter medium with an untreated melt-blown contact surface for increasing the contaminant absorption capacity. This melt-blown contact surface optimally causes the many small droplets to coalesce into larger ones. The particulate filter in the shape of a pleated star even agglomerates the finest water droplets.

The second filter phase consists of a water separator, whose hydrophobic fabric with a mesh width of 25 µm divides the barely stable emulsion, thus separating the water. As this occurs on the clean side of the filter, it is referred to as clean-side water separation.

Filter cartridges that are more economical and environmentally friendly

Spin-on fuel filters are designed for fast and easy replacement. Depending on their type, they are supplied with a thread to connect a water drain plug or water level sensor. For replaceable filter elements, only the dirty filter cartridge is replaced. These filter elements are also available in versions that can be completely incinerated easing the burden on the environment.

Inline fuel filters: Heat for diesels

Fuel preheating—the effective solution against paraffin separation

Experienced diesel drivers are familiar with the problem: when the temperature falls below zero, the vehicle is in danger of stopping. This is due to the tendency of the light oil used as fuel to form wax-like paraffin from -7 °C and below. The fuel takes on a gelatine-like consistency and flakes form. These flakes float towards the filter and clog its microporous surface. It may only take a short time until the fuel supply to the injection pump is interrupted. The result: the engine looses power—and then it stops; an annoying state of affairs.

Much has been done meanwhile to avoid this dilemma. First there is the 'insider tip' of mixing petrol into the diesel fuel. However, this can only be accepted in absolute emergencies, as the added petrol lowers the Centan number, which is essential for the ignition quality and thus for cold starting. Moreover, some diesel engines will not tolerate such mixtures. A widespread solution was the use of additives that could be added by the driver. However, it was necessary to add these already before the onset of the cold. Moreover, this runs the risk that the additives could affect performance and service life of the engines.

Nowadays, the oil companies are responding to this problem and sell so-called 'winter diesel' during the period from early November until the end of February. This diesel remains liquid down to -20 or -22 °C. However, if the temperatures drop even lower or if wind chill takes effect, trouble is still looming.

The optimum solution: A heat source for the diesel

The obvious solution is to supply the fuel at its optimum temperature. Two methods are available on the market for this purpose: firstly, electrically controlled warm-up with a small additional heat source—and secondly, heating by return flow, which is using the heat that is available anyway in the fuel flowing back from the injection pump.

This is because in modern high-pressure injection systems, high temperatures are generated in the return flow of the fuel. This heated-up fuel can then be added again to the feed line. The rate of recirculation can reach up to 100%. The response characteristics and the available amount of energy of these preheating systems result in high efficiencies.

Bimetal or wax element—the deciding difference

In conventional types of control, bimetals are used. However, this can cause problems, especially in the first minutes after a cold start, as a bimetal-preheating valve switches over instantly. Very cold fuel is then let into the filter, which is therefore again in danger of clogging.

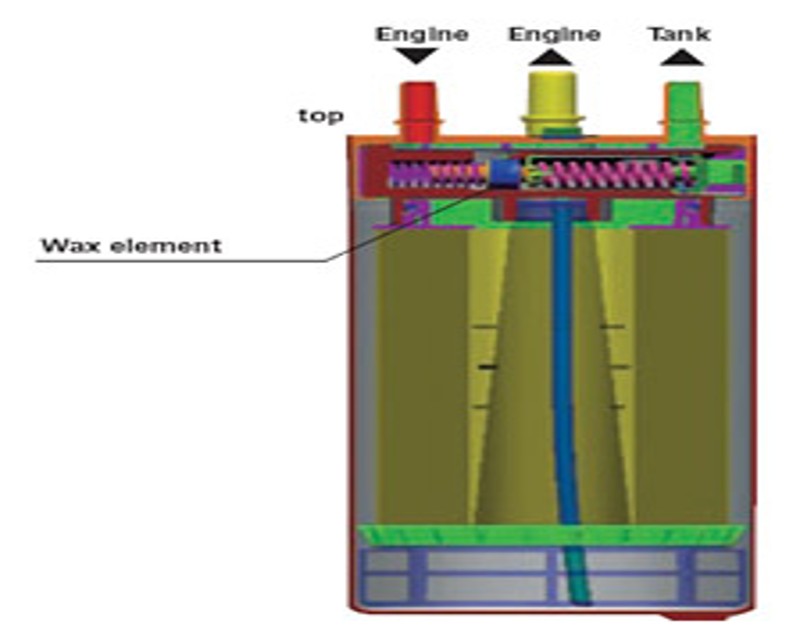

With continuous control via a wax element (as used in the MAHLE KL 229/3, for instance), the temperature of the fuel flowing to the engine becomes a controlled variable. In this way, the recirculation temperature can be optimised. In simple terms, the fuel temperature control works similar to a single lever mixer tap at the domestic washbasin: the ratio between warm and cold fuel is controlled continuously and matched to the requirements.

The wax element can be understood as a small hydraulic cylinder, which is filled with a particularly heat sensitive wax that expands when heated and then moves the control piston according to the temperature (see box). It can therefore respond to slightest temperature changes, offering significant advantages.

However, the KL 229/3 offers even more benefits. This is because the preheating system is here integrated into the filter—an economical design that also improves crash safety, as the amount of connections is reduced.

MAHLE inline fuel filters with integrated continuous temperature control are fitted, for instance, in the VW Touareg 2.5 l R5 TDI from 01/2003 onwards, in the VW Transporter 1.9 l TDI from 04/2003 onwards and in the VW Transporter 2.5 l TDI from 04/2003 onwards.

Temperature control via wax element

from -35 °C to +115 °C.

In position warm (closed), the fuel heated up by the highpressure pump is directly returned to the tank. In position cold (open), the hot fuel is added to the fuel coming from the tank.